Attention! When installing parts of the exhaust system, the joints of the connections must be airtight. Otherwise, when checking CO, deviations from the norm are inevitable.

Removing

1. Put the car on jack stands.

2. Spray all bolts and nuts of the exhaust system with a rust remover and let it work.

3. Cars with a gasoline engine. Unscrew the lambda probe.

4. Loosen the clamps of the rear muffler, release the muffler from the suspension cushions and disconnect it.

5. Support the pipes of the exhaust system with a wooden stand.

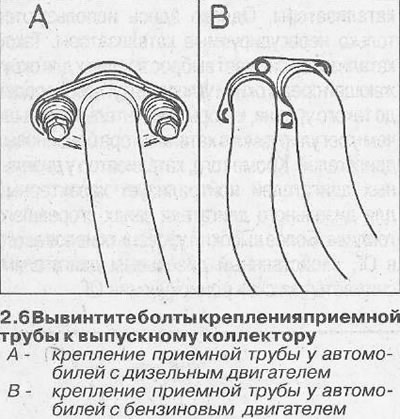

6. Unscrew the bolts securing the exhaust pipe to the exhaust manifold (see illustration). Vehicles with a diesel engine have springs on the mounting bolts.

7. Remove the clips from the muffler suspension rubber pads (see illustration).

8. Disconnect the front pipe from the bracket on the gearbox by unscrewing the mounting bolts (see illustration).

9. Release the pipes from the rubber suspension pads.

Attention! The catalyst is sensitive to impact, so do not hit it or let it fall.

Installation

10. Assemble the front of the exhaust system. Do not final tighten threaded connections. When assembling, replace the old bolts and seals with new ones, and also install new suspension pads to replace the damaged old ones. It is recommended to lubricate all bolts with a high temperature grease, such as Liqui Moly LM-508-ASC, so that they can be unscrewed the next time they are removed.

11. Secure the assembled exhaust system with a helper or place it on a wooden stand.

12. Fix the main muffler in the rubber pads. h

13. Fix a reception pipe on a final collector, having replaced former consolidations and bolts with new. Do not final tighten the bolts.

14. Connect the rear muffler pipe to the main muffler pipe by installing a mounting clamp on the connecting joint.

Attention! The mounting clamp is welded to the muffler connecting pipe.

15. Straighten the position of the rear muffler and fix it in the suspension pads, and fix the pads with clips.

16. Fix a reception pipe in an arm of a transmission.

17. Straighten the pipes of the exhaust system so that they are stress-free, run in accordance with the contour of the bottom and are at a sufficient distance from the body.

18. Cars with a gasoline engine. Screw the lambda probe into the downpipe.

19. Tighten the screw connections.

Tightening torques for threaded connections:

- Downpipe to exhaust manifold, 4-cylinder engines - 25 Nm

- Muffler downpipe to exhaust manifold, 6-cylinder engines - 30 Nm

- Mounting clamp on the rear muffler - 20 Nm

- Catalyst clamp to muffler - 25 Nm

- Downpipe bracket to gearbox - 20 Nm

20. Cars with a diesel engine. Fasten front exhaust pipe to turbocharger bracket. Bolted springs should be compressed to 27-28 mm.

21. Check the exhaust system for leaks. To do this, leave the engine running at idle and plug the exhaust pipe with a rag. The engine should run intermittently or stall, otherwise the system is leaking. Find and fix leaks.

Visitor comments