Vehicles with a 2.5L diesel engine

For the test, a measuring device with a pointer indication is required, as well as an appropriate adapter for screwing to the pump. During the test, the engine must be cold, but not below +20°C.

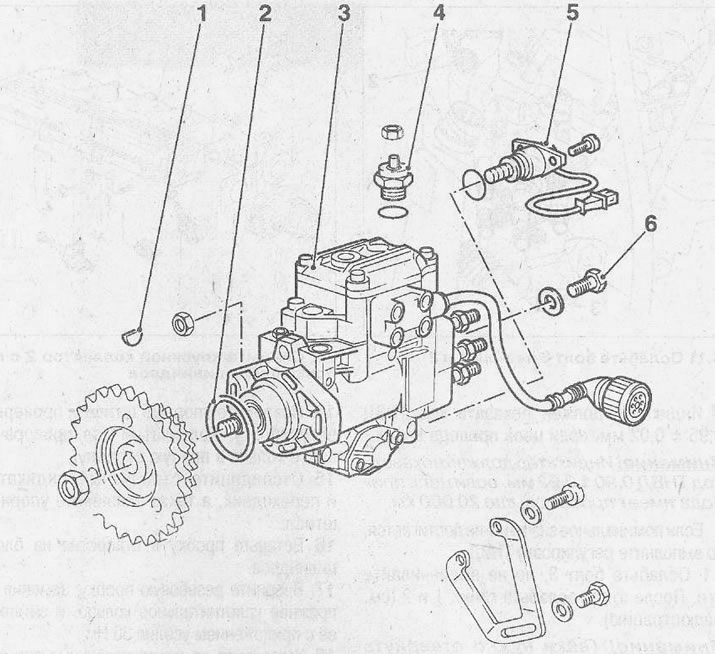

6.0 injection pump of a car with a diesel engine of 2.5 liters

1 - gear key on the shaft

2 - stuffing box

3 - injection pump

4 - fuel shutoff solenoid valve

5 - fuel injection advance solenoid valve

6 - screw plug

1. Disconnect the wire terminal «masses» (-) negative terminal of the battery.

2. Remove the engine compartment protection

3. Remove the intake manifold.

4. Cars with air conditioning.

Remove the viscous clutch from the radiator fan.

5. Unscrew the screw plug 1 on the injection pump (see illustration).

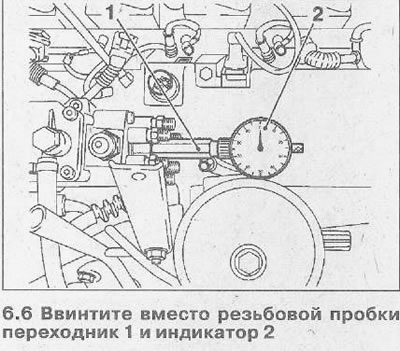

6. Screw in adapter 1 OPEL KM-226-A and indicator 2 KM-571-B instead of the screw plug (see illustration).

7. Rotate the crankshaft of the engine clockwise in the direction of the TDC of the piston of cylinder No. 1 until the indicator needle stops for a while. The start of the turn should be 60-90°before TDC.

The piston of cylinder No. 1 is at TDC when both cams of the valve actuator of cylinder No. 1, located near the timing chain, are facing upwards. To control, remove the oil filler cap and monitor the position of the cams.

To rotate the crankshaft, engage 5th gear, release the parking brake and push the vehicle. You can also apply the parking brake, put the gear in neutral and rotate the crankshaft at the center bolt of the accessory drive ribbed pulley.

8. Reset the indicator to «0».

9. Remove plug 1 from the cylinder block (see illustration).

10. Rotate the crankshaft two turns clockwise so that you can insert the OPEL-813 thrust pin or roller of the appropriate diameter into the hole on the cylinder block and into the flywheel to fix the engine at TDC.

Attention! Do not turn the crankshaft against the direction of the engine. This will lead to incorrect values when checking the start of injection pump injection.

Attention! The indicator should show the stroke of the injection pump 0.90±0.02 mm if the drive chain has a mileage of over 20,000 km.

If the nominal value is not reached, then adjust the injection pump.

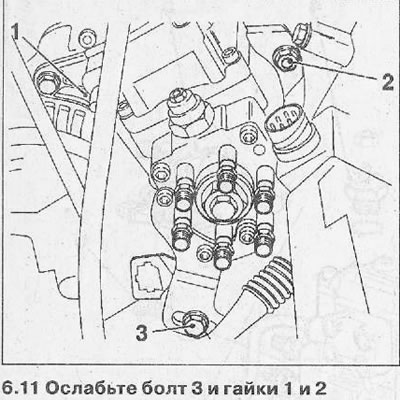

11. Loosen bolt 3, but do not unscrew it. Then loosen nuts 1 and 2 (see illustration).

Attention! Nuts need to be unscrewed only 2-3 turns. Loosening the nuts more than this number of turns may cause seizing due to tension on the drive chain.

12. Turn the injection pump and achieve the desired stroke of the injection pump, which should show the indicator.

13. Tighten the nuts and bolt in sequence from 1 to 3 with a torque of 25 Nm (see illustration 6.11).

14. Remove the thrust pin and check the adjustment. Turn the crankshaft only to the right.

15. Disconnect the dial gauge and adapter and remove the thrust pin.

16. Insert the plug into the hole on the cylinder block.

17. Screw in the screw plug, replacing its previous sealing ring, and tighten it with a force of 30 Nm.

18. Reinstall the remaining components that were removed.

19. Start the engine. If necessary, remove air from the engine power supply system.

20. Carry out a test drive and check the tightness of the screw plug. Tighten the plug if necessary.

Visitor comments