2. Raise the front of the car and remove the road wheel (see Chapter 9, Section 3).

3. Disconnect the anti-roll rod end link.

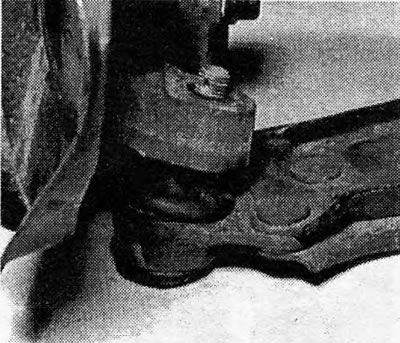

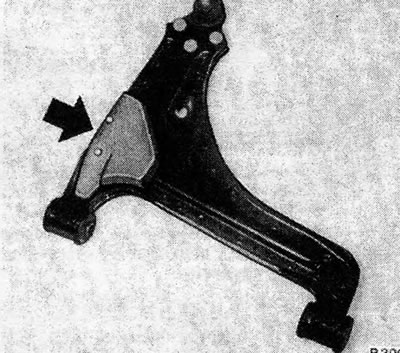

4. Using a suitable tool, remove the control bracket ball joint from the short axle holder (see Section 3, paragraph 6) (photo).

Photo 6.4A Control bracket ball joint.

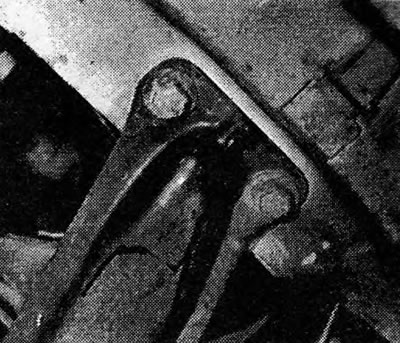

Photo 6.4B The control bracket ball joint is disconnected.

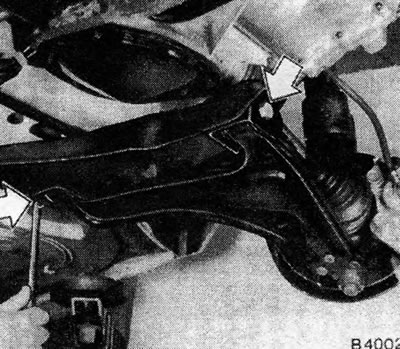

5. Unscrew the control bracket bolts from the support. On some newer models, the control bracket support is extended and attached to the chassis cross member at the front; Removing the control bracket from a support of this type is carried out in the same way (photo).

Photo 6.5 Front mounting of the long type control bracket support.

6. Assembly is carried out in the reverse order, but it is necessary to clear the threads under the support bolts from the mixture blocking the threads by screwing a thread cutting device into the holes (M12x1.75). Now you must use new bolts. They should already be coated with a thread blocking compound; Just make sure that these bolts are no more than 5 years old, otherwise the mixture will no longer be effective. You can determine the year of manufacture by the numbers on the bolt heads, which represent the last two digits of the year.

7. While tightening the bolts, keep the control bracket horizontal; tighten the bolts to the specified torque.

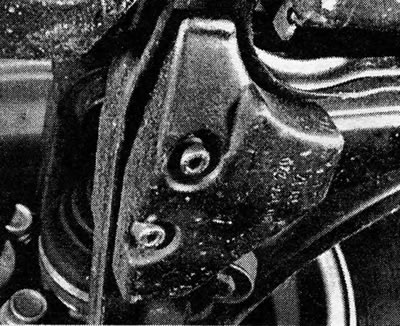

8. A shock-absorbing weight is installed on the right-hand control bracket on models 1.6 and 1.8 (Pic. 10.7). It is secured with socket-head screws (photo).

Photo 6.8 Shock-absorbing weight of the right-hand control bracket.

Pic. 10.6. Unscrew the control bracket bolts - indicated by arrows

Pic. 10.7. Shock-absorbing weight of the control bracket - indicated by the arrow

Visitor comments