2. Disassembly of the distributor should be done on a clean work table, where the removed parts can be laid out in order.

3. Remove the moisture-proof casing and distributor cover along with the wires (if it hasn't been done yet) (see section 3). Remove the slider and plastic plate.

4. Remove the breaker (see section 4).

5. Remove the capacitor (see section 5).

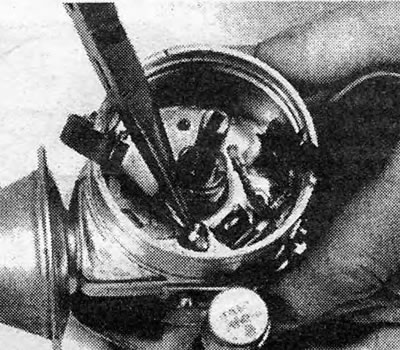

6. Remove the retaining ring securing the vacuum regulator control rod to the plate roller (see photo).

Photo 7.6. Removing the retaining ring of the vacuum regulator rod.

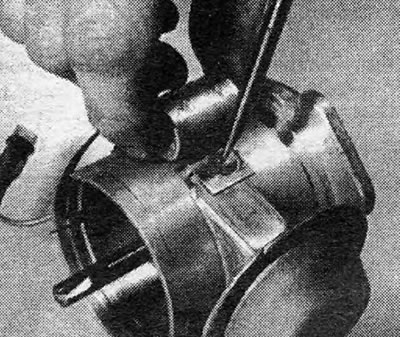

7. Unscrew the screws securing the vacuum regulator and remove it, disconnecting the control rod (see photos).

Photo 7.7A. Screw securing the condenser and vacuum regulator.

Photo 7.7B. Disconnecting the vacuum regulator control rod.

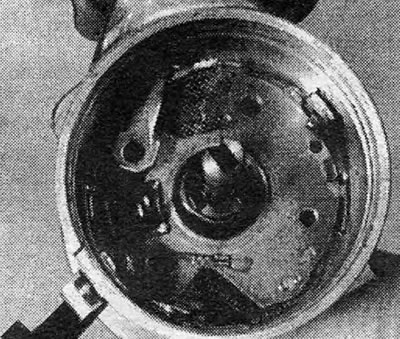

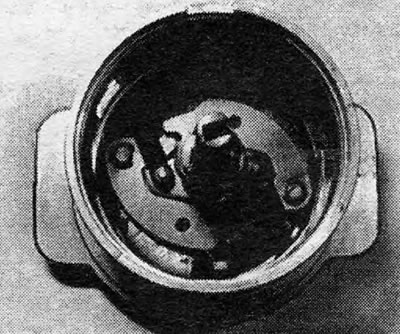

8. Remove the screws and remove the support plate (see photos).

Photo 7.8A. Removing the screw securing the base plate and clamp.

Photo 7.8B. Removing the base plate.

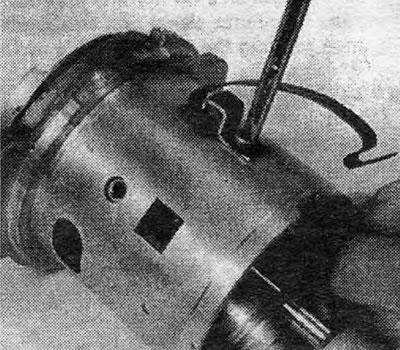

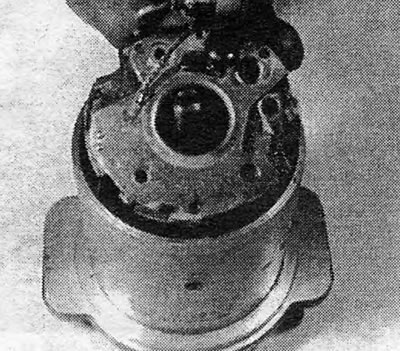

9. Inspect and, if necessary, remove the weights and springs of the centrifugal governor, noting their relative position (see photos).

Photo 7.9. Weights and springs of the centrifugal regulator.

10. To remove the roller, you must first remove the drive arm. Using a small punch, drive the pin out and pull the roller out through the top.

11. Clean all parts with a grease solvent and wipe them dry or dry them with compressed air.

12. Inspect all parts for obvious wear and damage. Check the roller play and inspect the drive gear teeth or pawl surfaces for wear. Replace damaged or questionable parts.

13. Before assembling the distributor, lubricate all moving parts and springs of the centrifugal weights with grease.

14. Reinstall the shaft and drive gear or pawl. Lock the gear (dog) new pin.

15. Assemble the centrifugal regulator, ensuring that the weights and springs are installed correctly.

16. Install the contact breaker plates and tighten the screws securing them.

17. Reinstall the vacuum regulator and tighten the screws securing it. Connect the control rod to the shaft and secure it with a locking ring. Apply a little lubricant to the roller.

18. Install the capacitor (see section 5).

19. Install a contact breaker (see section 4) and adjust the contact gap (see section 3).

20. Lubricate the moving parts of the breaker support plate with clean engine oil and apply a small amount of high temperature grease to the surface of the cam.

21. Check the roller for free rotation and the breaker contacts for correct operation. Use your finger to turn the slider in the direction opposite to its normal direction of rotation: it should return back to its original static position.

22. The distributor is ready for installation on the engine.

Visitor comments