Leaded fuel

1. The ignition must be adjusted if it was knocked down after overhauling or removing the distributor. The following procedures are based on a standard engine in normal condition. It is also assumed that the engine is running on the recommended high octane fuel.

2. Place the transmission in neutral and remove all 4 spark plugs.

3. Close the spark plug hole of cylinder Nin with your thumb and turn the engine clockwise using a wrench placed on the crankshaft pulley bolt so that pressure begins to be felt in cylinder No. 1. This indicates that the piston of cylinder No. 1 is approaching TDC. on the ignition stroke of the mixture.

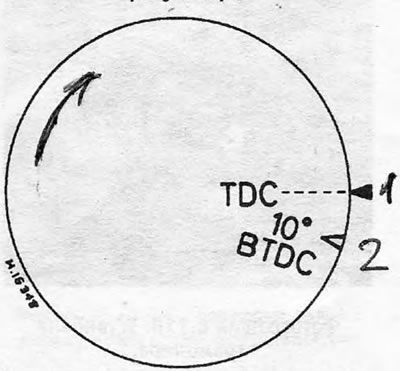

Pic. 4.3. A mark on the crankshaft pulley that allows you to set the ignition timing to 10 degrees, up to TDC. The relative position of the v.m.t. is shown.:1. V.m.t.; 2. 10 degrees, b.m.t.

4. Continue rotating the crankshaft until the mark on the crankshaft pulley aligns with the mark or pointer on the camshaft belt cover.

5. In this position, the ignition is set to the desired angle to TDC. (the alignment of the marks corresponds not to the TDC, but to the required ignition timing).

6. Loosen the clamping bolt or nut of the distributor and turn the distributor body so that the breaker contacts just begin to open. Tighten the clamp bolt or nut.

7. Sometimes it is difficult to determine the moment when the contacts begin to open.

In order to determine it more accurately, you should connect a 12 V lamp in parallel with the contacts (one wire per "mass" and one - to the low voltage terminal of the distributor). Turn on the ignition and turn the distributor housing until the lamp lights up, indicating that the contacts have just opened.

8. If you cannot correctly align the slider with the mark on the rim of the distributor housing, this means that the breaker cam is not installed correctly on the drive shaft. To install the cam correctly, you will have to partially disassemble the distributor and check the position of the cam relative to the centrifugal regulator: it may be turned 180 degrees relative to the correct position.

9. Check the ignition adjustment using a strobe lamp.

10. Apply white paint to the mark on the crankshaft pulley and the timing mark or pointer on the camshaft belt cover and connect a strobe light to the high voltage circuit of the No. 1 cylinder according to the manufacturer's instructions. Disconnect the vacuum tube from the vacuum regulator.

11. Start the engine and let it idle. Direct the light of the lamp towards the alignment marks. In the light of the lamp, the marks should appear aligned. Open the throttle slightly and check that as the engine speed increases, the mark on the crankshaft pulley moves away from the pointer, which indicates the correct operation of the centrifugal regulator.

12. If the marks do not align in the light of the lamp, loosen the distributor clamp bolt and carefully turn the distributor so that the marks are aligned. Tighten the clamp bolt.

High octane unleaded fuel

13. The engines on the models in question can run on unleaded fuel, however, the manufacturer recommends reducing the ignition timing on carburetor engines by 5 degrees when detonation occurs.

14. There is only one mark on the crankshaft pulley, corresponding to 10 degrees BT, so in order to delay the ignition, additional marks will have to be applied.

15. Turn the engine using a wrench placed over the crankshaft pulley bolt (or by setting a higher gear and pushing the car forward), so that piston No. 1 is at i.d.t. on the ignition stroke of the mixture. (This can be checked by removing spark plug No. 1 and closing the spark plug hole with your thumb: pressure should be felt as the piston rises). You can accurately check whether the piston is in the top position using a knitting needle inserted into the spark plug hole.

16. Make a mark on the crankshaft pulley opposite the mark or pointer on the engine.

17. The original mark on the crankshaft pulley corresponds to 10 degrees, b.m.t., and the new mark you made corresponds to t.m.t. That. position 5 degrees, up to t.m.t. should be halfway between these two marks.

18. Make another mark on the pulley, corresponding to 5 degrees, up to TDC. and adjust the ignition, as indicated in paragraphs 11 and 12, but relative to the new mark for 5 degrees, up to TDC.

19. It should be noted that 5 deg. - this is the maximum ignition retardation angle. It is possible that detonation will be eliminated more effectively at a lower angle (experiment to find the optimal solution).

Visitor comments