2. Disconnect the wires from the battery and remove it.

3. Disconnect the grounding bus from the box.

4. Disconnect the downshift cable from the carburetor and gearbox.

5. Disconnect the gear lever cable from the lever on the box.

b. Remove the mounting clip. Remove the lever from the box.

7. Unscrew the gear lever cable support bracket. There is no need to disconnect the cable from the bracket.

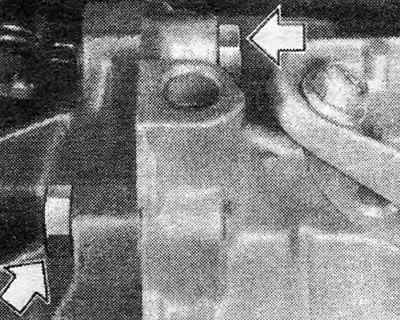

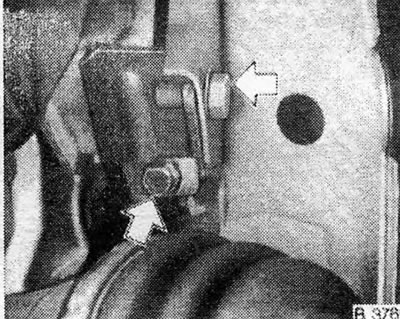

8. Unscrew and remove the bolts securing the torque converter housing to the engine (see fig. 6.51).

9. Remove the remaining bolt, remove the starter and tie it to the side with wire. There is no need to disconnect the electrical wiring from the starter.

10. Disconnect the speedometer cable from the gearbox.

11. Remove the transmission fluid dipstick.

12. Raise the front of the car so that the box can be pulled out through the front.

13. Remove the front left wheel.

14. Connect the hoist to the engine or support it with a jack.

15. Disconnect the left rear fastening of the box to the machine body.

16. Disconnect the anti-roll bar from the lower left suspension arm.

17. Disconnect the lower left suspension arm support from the machine body (see chapter 10).

18. Disconnect the left drive shaft from the gearbox (see chapter 7).

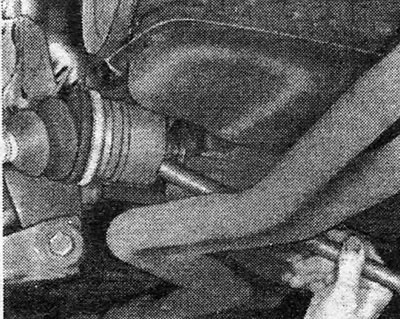

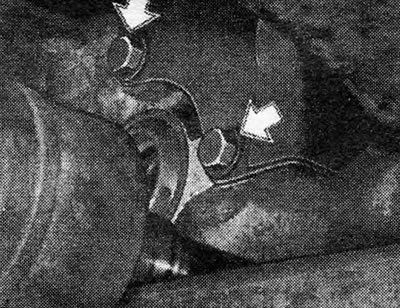

19. Disconnect the right drive shaft from the gearbox (see chapter 7).

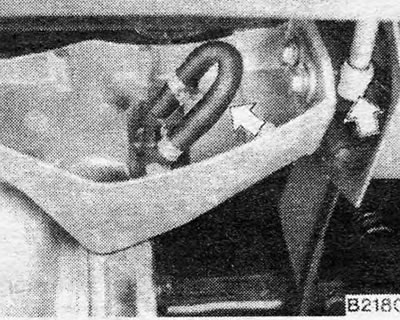

20. Disconnect the oil cooler pipes at the gearbox and plug their open ends (see fig. 6.53).

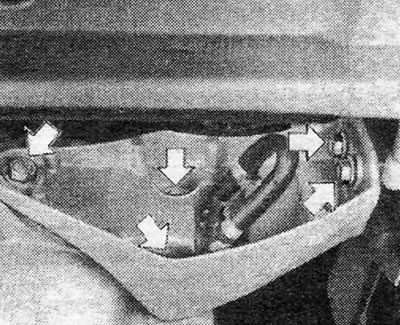

21. Remove the bolts and remove the torque converter cover (see fig. 6.54).

22. Remove the bolts securing the drive disk to the torque converter. In order to be able to get to each of the bolts, you need to turn the drive disk (using a wrench placed over the crankshaft pulley bolt or vibration damper bolt - these bolts must be replaced when installing the box). When removing each bolt, it is necessary to block the starter ring gear.

23. Remove the bolts and remove the left front cushion (see fig. 6.56).

24. Unscrew the exhaust system pipe bracket bolts and turn the bracket up (see fig. 6.57).

25. Pull out the dipstick tube (Be prepared for some transmission fluid to spill).

26. Support the box with a garage jack.

27. Working under the machine, remove the left rear support bracket from the machine body. Also remove 2 bolts from the engine support bracket (see fig. 6.58 and 6.59).

28. Move the box away from the engine so that it comes off the locating pins and then lower it on the jack. Pull the box out from under the car through the front.

29. The box is installed in the reverse order. Please note the following points.

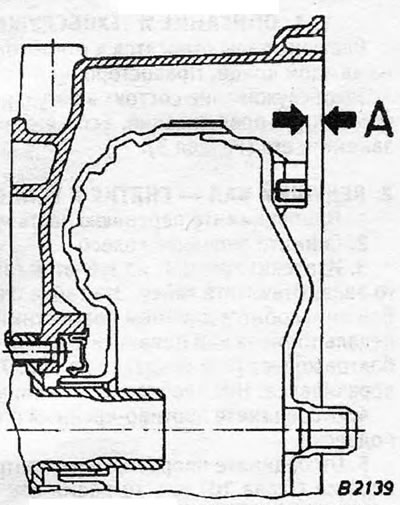

30. Before attaching the box to the engine, check that the torque converter is fully engaged with the oil pump. To do this, measure the size "A" (see picture), which should be equal to 9.00-10.00 mm. When obtaining a different value, turn the torque converter while pressing on it with your hand (see fig. 6.60).

31. Apply a little molybdenum disulfide grease to the torque converter guide collar.

32. When attaching the torque converter to the drive disk, align the white mark on the disk with the colored mark on the torque converter.

33. Connect the downshift cable first to the gearbox and then to the carburetor, and adjust it as indicated in section 23.

34. Pour transmission fluid into the box (see section 22).

35. Check that all bolts and nuts are tightened to the correct torque and that thread locking compound is applied to the threads of the suspension arm support bolts.

Pic. 6.51. Bolts securing the torque converter housing to the engine (shown by arrows)

Pic. 6.52. Disconnect the right drive shaft from the box using a bit

Pic. 6.53. Disconnection points for oil cooler pipes at the gearbox (shown by arrows)

Pic. 6.54. Torque converter cover bolts (shown by arrows)

Pic. 6.55. Removing the bolts securing the torque converter to the drive disc

Pic. 6.56. Left front airbag bolts (shown by arrows)

Pic. 6.57. Bolts securing the exhaust pipe bracket to the gearbox (shown by arrows)

Pic. 6.58. Left Rear Support Bracket Bolts (shown by arrows)

Pic. 6.59. Bolts securing the transmission to the engine support bracket (shown by arrows)

Pic. 6.60. Checking the torque converter position: A = 9.0-10.0 mm.

Visitor comments