Checking the transmission fluid level and adding fluid to the box

1. It is extremely important to maintain the correct level of transmission fluid in the box.

2. The fluid level can be checked on a cold or hot box.

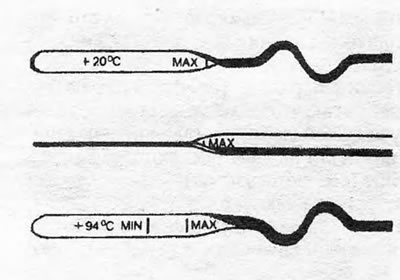

3. To check the fluid level on a cold box, place the car on a level surface with the engine running and the gear lever set to "R". Pull out the dipstick, wipe it with a lint-free cloth, replace it and pull it out again. Check the fluid level on the side of the dipstick with the number on it "+20°С". The level should be at the MAX mark (see Fig.6.39).

Pic. 6.39. Marks on the automatic transmission dipstick

4. To check the fluid level on the hot box, you should first travel about 15 km. Check the fluid level as indicated above, but use the side of the dipstick with the number on it "+94°С". The level should be between the MIN and MAX marks.

5. The above checks should be carried out with the engine idling for approximately 1 minute, but no longer than 3 minutes, because otherwise you may get incorrect readings.

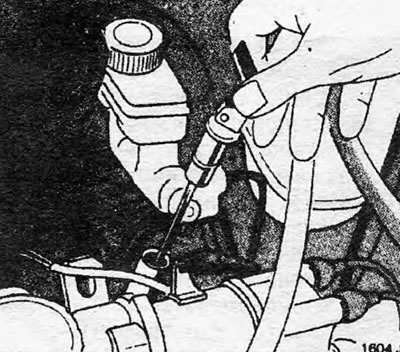

6. If necessary, add fluid into the box through the dipstick tube. Check that the liquid is absolutely clean. Be careful not to pour fluid past the MAX mark (see Fig.6.40).

Pic. 6.40. Transmission fluid dipstick tube on an automatic transmission

7. When the box is cold, dropping the fluid level by 5.0 mm below the MAX mark indicates the need to add 0.25 liters of fluid.

Replacing transmission fluid

8. Transmission fluid must be replaced at the intervals specified in section "Routine Maintenance" at the beginning of this Guide. When operating the machine in dusty conditions or when frequently towing a trailer, the fluid should be changed more frequently.

9. Before draining the transmission fluid, you must let the box cool down to avoid getting burned.

10. Remove all screws of the box tray except one, which must be loosened a few turns.

11. Disconnect the pan from its gasket and, when its edge goes down, drain the liquid into a suitable container.

12. Remove the remaining screw and remove the pan. Remove any traces of old gasket or sealant from the flange.

13. Remove the strainer from the mounting clips, clean it in gasoline and allow to dry.

14. Replace the sealing ring that opened after removing the filter and put the filter back in place.

15. Reinstall the pan with a new gasket and secure it with bolts. Some boxes use silicone sealant instead of a gasket. In this case, it is necessary to apply a strip of sealant approximately 5.0 mm wide to the cleaned contact surfaces. The pan, which must be installed with a gasket, can be identified by the stiffeners on the flanges of the pan. The pan installed on the sealant has flat flanges.

16. Pour the required amount of transmission fluid into the box and check its level, as described earlier for the case of a cold box.

17. If, when draining the old fluid, it turns out that it has lost color, then the cause of this may be overheating of the box.

18. Between the MIN and MAX marks on the dipstick there is 0.5 liters of liquid.

Visitor comments