The 2.4 liter engine has a camshaft chain drive.

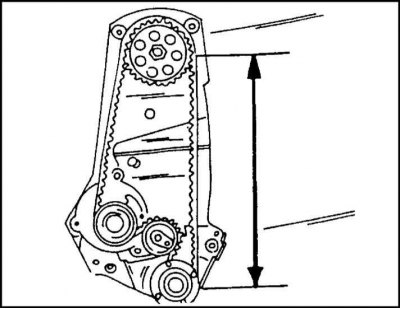

Checking the toothed belt tension

ONS engine until mid-1995 release

Checking and tensioning the toothed belt should be carried out on a cold engine. This operation is carried out differently for an engine with a toothed belt tensioner and without a tensioner.

Engine with toothed belt tensioner

1. Remove the viscous coupling with the fan and brackets as described in the relevant subsection.

2. Remove the alternator drive belt and power steering pump.

3. Remove the shield under the car.

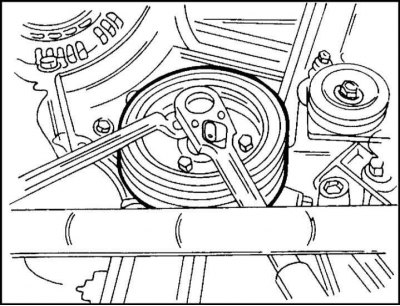

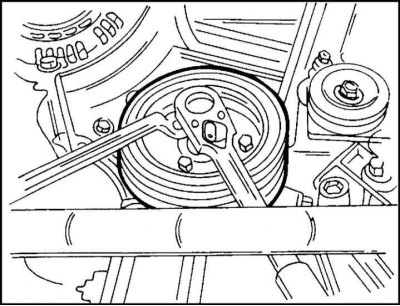

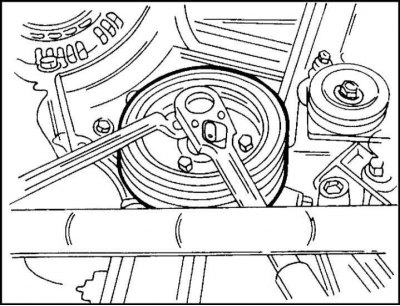

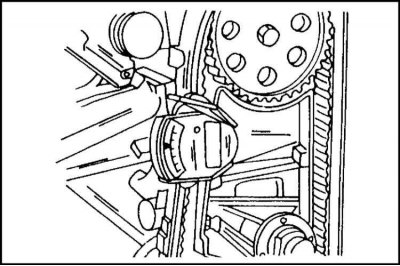

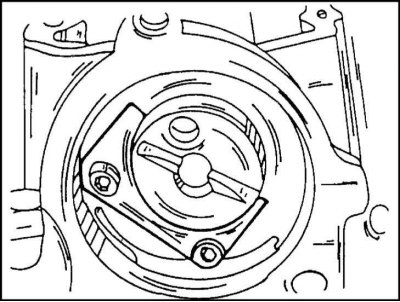

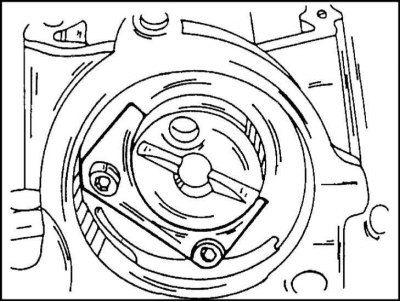

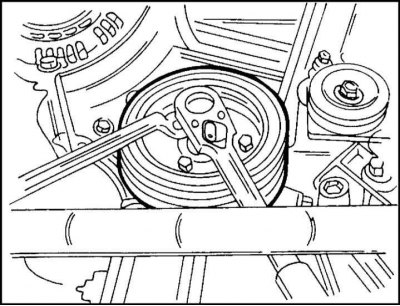

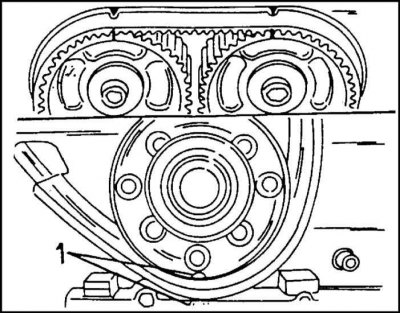

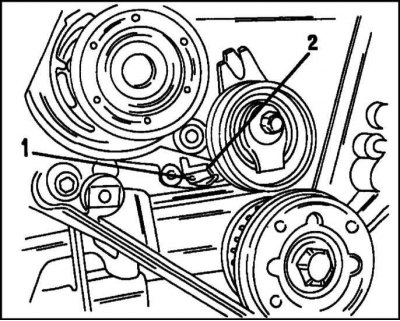

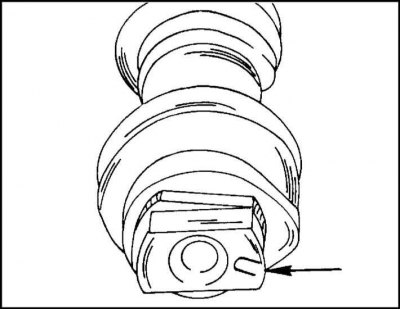

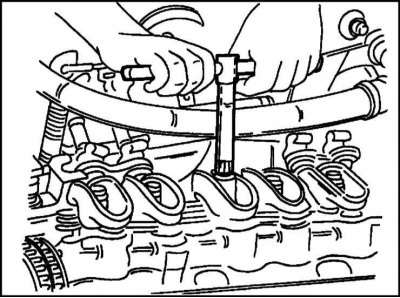

4. Turn out four bolts of fastening of a pulley of a cranked shaft. The pulley is kept from turning with a socket wrench, as shown in illustration.

5. Remove the front toothed belt cover.

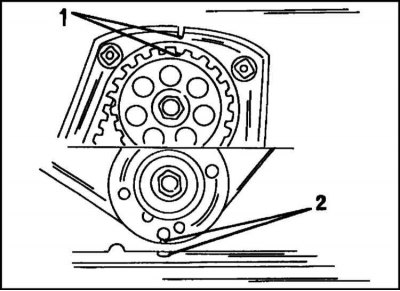

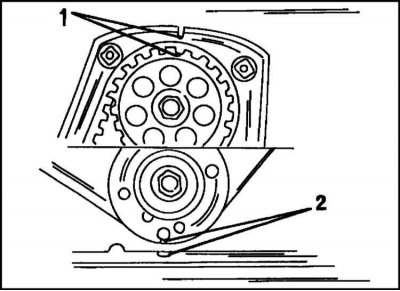

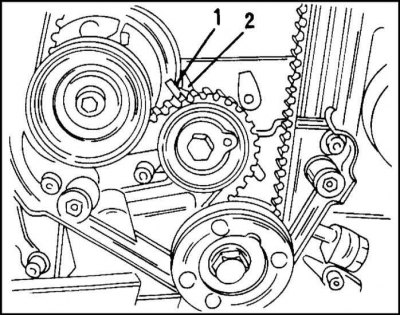

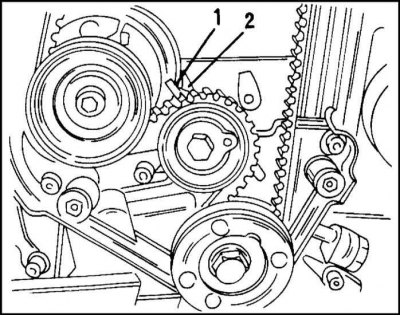

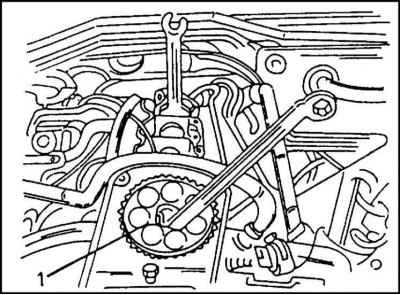

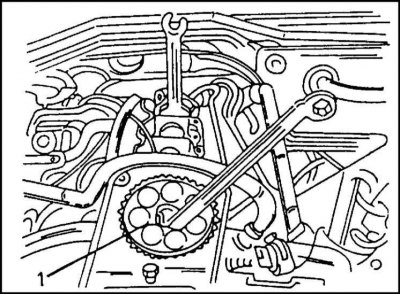

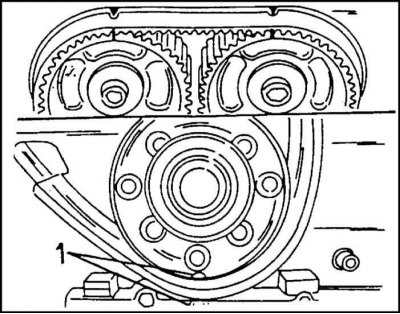

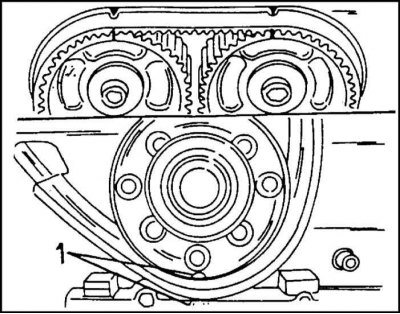

6. Turn the crankshaft in the direction of rotation with a socket wrench so that the marks (2) matched (illustrations). Labels must match at the same time (1) on the camshaft sprocket and the bar behind the toothed belt.

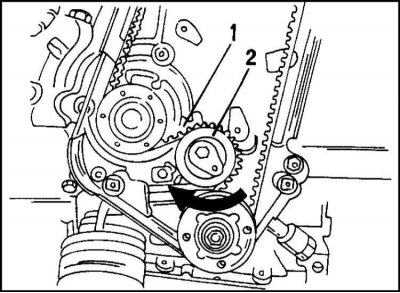

7. Check the water pump drive pulley. The lug on the pump must match the corresponding protrusion on the cylinder block, as shown in illustration.

8. Check toothed belt tension. The belt is tensioned normally if the pointer (2) located 4 mm to the left of the mark (2) no illustrations. This check is valid for a used belt. A different standard applies to a new belt (see section Replacing the toothed belt below).

9. If the tension of the toothed belt does not match the above, it is necessary to carry out the adjustment as described in section "Toothed belt replacement".

Now the engine can be assembled. Tighten the pulley mounting bolts to 20 Nm. Installation of a viscous coupling, V-belt, etc. described in the relevant sections.

Engine without toothed belt tensioner

To check the tension of the toothed belt for these engines, there is a special tool from Opel (No. KM-510-A). If it is not available, then the check is performed by the car owner himself based on his own experience. However, this tension needs to be checked later in a workshop.

Checking the belt tension is described below in the Timing Belt Replacement for Engines Without Tensioner Pulley section.

Toothed belt replacement

Idler pulley motor

1. Disconnect the ground cable from the battery.

2. Mark the direction of rotation of the belt on the belt with paint and remove the belt as described in Chapter Cooling and heating systems.

3. Place the car on stands at the front.

4. Remove the shield under the car.

5. While holding the crankshaft from turning as shown in the illustration, remove the vibration damper mounting bolts. Remove the damper.

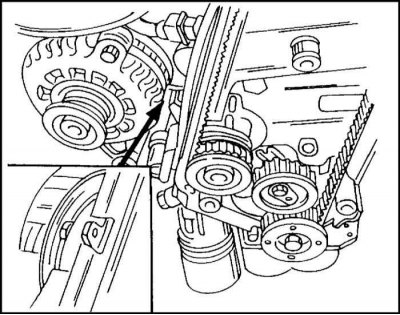

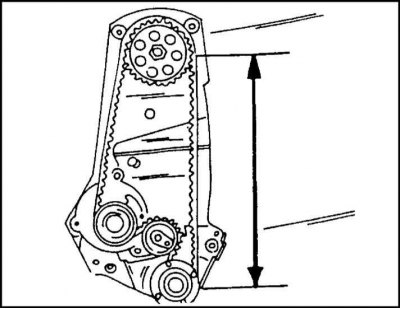

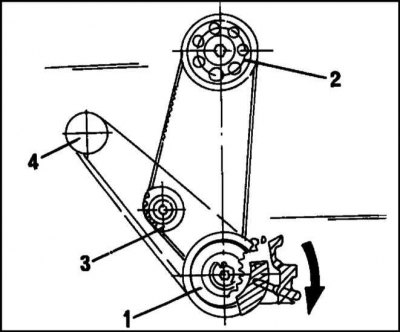

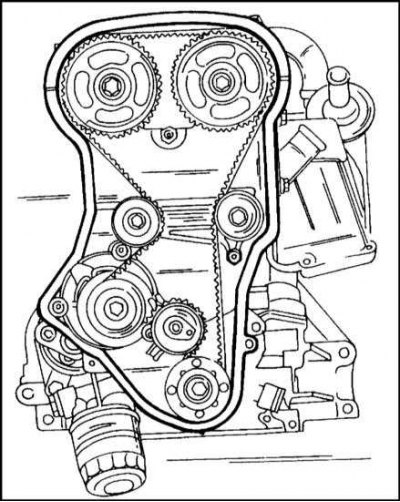

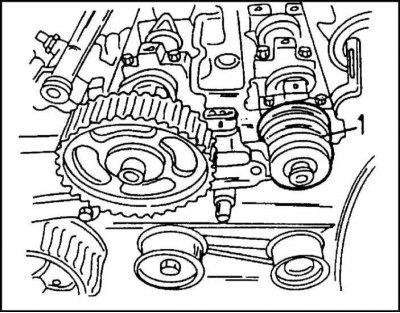

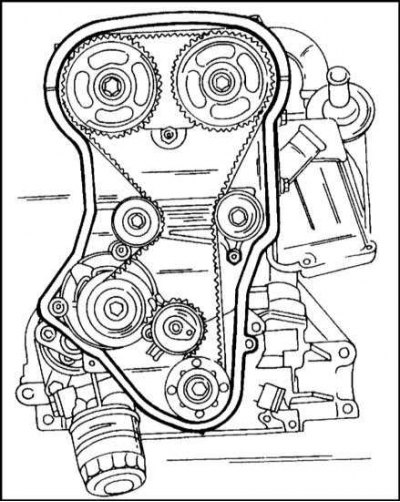

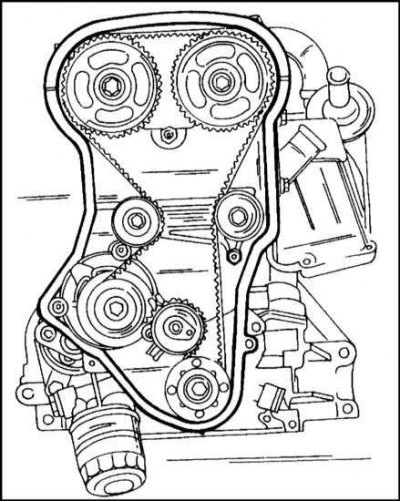

6. Disconnect the cable mount from the toothed belt cover and remove the cover. The layout of the toothed belt is shown in illustration. Install the belt so that its tensioned branch is between the lines indicated by the arrows in the drawing.

7. Turn the crankshaft in the direction of rotation with a socket wrench so that the marks (2) matched (illustrations). Labels must match at the same time (1) on the camshaft sprocket and the bar behind the toothed belt.

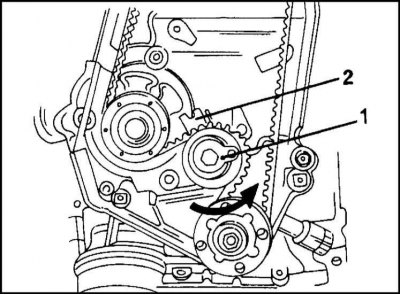

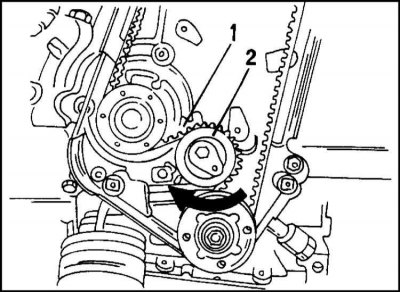

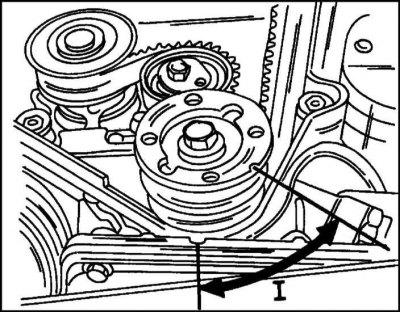

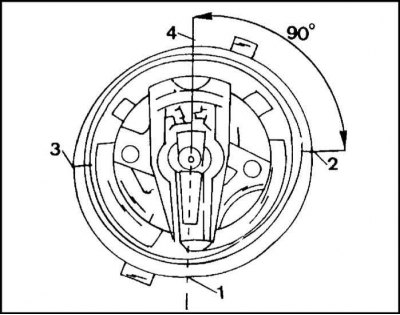

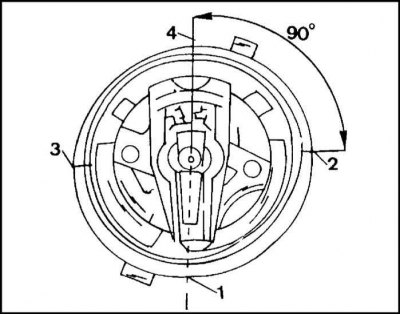

8. Loosen the tension roller fixing bolt and turn the adjusting eccentric to the right in the direction of the arrow, as shown in the illustration, so that the pointer (1) stood opposite the left stop.

The belt is now loose and can be removed.

Instruction. If the belt is to be used again, it must be prevented from contact with oil, grease and kinks. It is best to store the belt on the wall by hanging it on a nail.

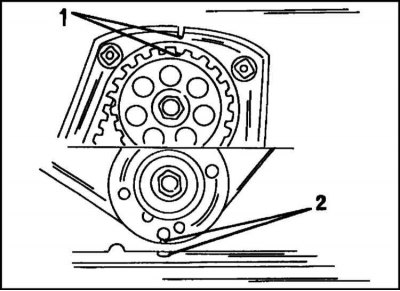

9. Check that the camshaft and crankshaft are in the position shown in illustration. Otherwise, turn the shaft very slowly (s). The pistons may hit the valves. As soon as this is felt, turn the second shaft back.

The coolant pump drive pulley should also be checked as it may not have rotated correctly. The lug on the pump housing must match the corresponding projection on the cylinder block.

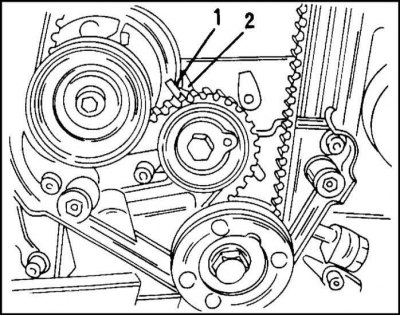

10. Put on a gear belt according to illustr. point 1 on the gears. Branch 1 of the belt must be taut. Now you need to tighten the belt. The belt is correctly tensioned if the indicator (1) matches label (2), as shown in illustration. Further, we consider cases where the specified match does not exist.

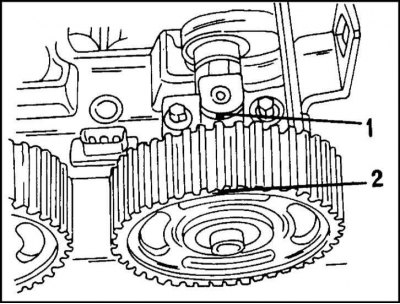

11. Loosen the bolt in the roller tension center and turn the adjusting eccentric (1) on illustration to the left so that the pointer (2) stuck to the right side. Tighten the roller bolt again (25 Nm).

12. Rotate the crankshaft exactly two turns (using a socket wrench for the pulley bolt) and check if the labels shown in fig.

13. Slightly loosen the idler pulley mounting bolt and turn the adjusting eccentric to the right (clockwise) so that the pointer (1) and label (2) lay opposite each other, as shown in the illustration. Tighten the bolt again to 25 Nm.

14. Rotate the crankshaft again two full turns and check the position of the eccentric marks and pointer.

Carry out other work in reverse order. Tighten the vibration damper with a torque of 20 Nm. Put on the V-belt, taking into account the direction of its rotation and tension, as described in Chapter Cooling and heating systems.

Reinstall all removed parts.

Engine without toothed belt tensioner

1. Disconnect the ground cable from the battery.

2. Remove the viscous coupling with fan and fan shroud (see related instructions).

3. Turn out "Torx" fan pulley bolts. Remove the fan.

4. Remove the top part of the front toothed belt cover.

5. Turn the crankshaft so that the piston of the first cylinder is at TDC.

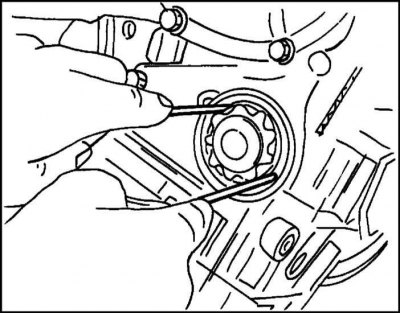

6. Turn away a bolt of fastening of a pulley, as it is shown on illustr.

7. Remove the lower part of the toothed belt cover.

8. Loosen the three coolant pump mounting bolts and push the pump to the side so that the toothed belt is loose and can be removed.

4 - Generator

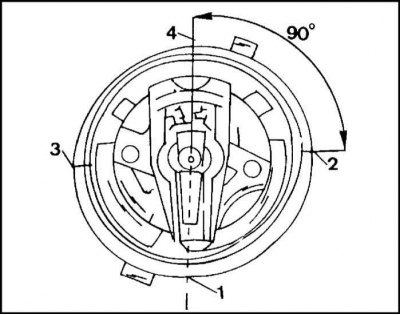

9. Put on a new gear belt according to fig. First put the belt on the crankshaft wheel (1), then to the camshaft wheels (2) and coolant pump (3).

10. Now install the crankshaft pulley.

Adjust the toothed belt tension. To check the tension of the toothed belt for these engines, there is a special tool from Opel (No. KM-510-A). If it is not available, then the check is performed by the car owner himself based on his own experience. However, this requires later verification in a workshop environment.

Checking the belt tension is described below in the section "Toothed belt replacement" for engines without idler.

Instruction. The tension of a used belt is checked with a warm engine. The tension of the new belt is checked on a cold engine.

The following describes how to check belt tension on an installed engine.

1. Slide the coolant pump outward, allowing some freedom to the drive belt, and finger-tighten the pump mounting bolts.

2. Install the socket on the crankshaft pulley bolt and turn the crankshaft from its current position at least a quarter of a turn to the right.

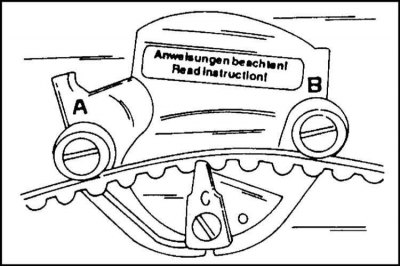

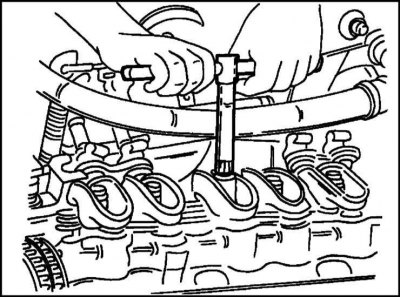

3a. Belt tension gauge shown in fig.

3b. Install the device as shown in fig. (between the wheels of the coolant pump and the camshaft).

4. Slowly release the instrument lever, tap the instrument two or three times and take a reading.

Below are the instrument readings for cold and warm engines. They should not be confused.

5. If the meter reading does not match the above, loosen the coolant pump mounting bolts and rotate the pump. Turning outward increases belt tension, turning inward reduces tension. Tighten the pump mounting bolts again by hand (the pump can no longer be moved).

6. Remove the instrument and rotate the crankshaft two full turns to the right. Recheck the belt tension as described above. If it corresponds to the values given above, tighten the pump mounting bolts. Install the toothed belt covers. Attach the cable harness to the cover.

7. If the above device for monitoring the belt tension is not available, the tension is checked manually on the belt branch between the wheels of the coolant pump and the camshaft. To do this, try to turn the belt tape with your thumb and forefinger. If the belt can be turned 90°, the tension is correct. It's better to overtighten the belt a little than undertighten it. A loose belt can jump over the teeth of the wheel. Tension adjustment must also be carried out on the coolant pump. Additional checks will not be superfluous. A control check must be carried out in a workshop. A belt jumping over the teeth can cause severe engine damage and at the very least costly repairs.

OHC 2.0 L engine from mid-1995 release

The camshaft drive corresponds to the drive of the engines of the latest model. Timing belt tension control corresponds to the control described above. A toothed belt with a tension roller is installed here, i.e. it is necessary to follow the instructions given in subsection Engine with toothed belt tensioner in Section Checking toothed belt tension and instructions for replacing the toothed belt in subsection Engine with toothed belt tensioner in Section Replacing the belt. The belt lining is shown in fig. to point 9.

Camshaft seals

The removal and installation of the oil seal in the camshaft housing on the distribution drive side and on the gearbox side are different. Both seals can be replaced without removing the engine.

Replacing the oil seal on the drive side of the camshaft

1. Disconnect the cable harness and both hoses from the camshaft bearing housing cover. Now you can remove the toothed belt as described above. Keep in mind the differences in the design of the camshaft drive.

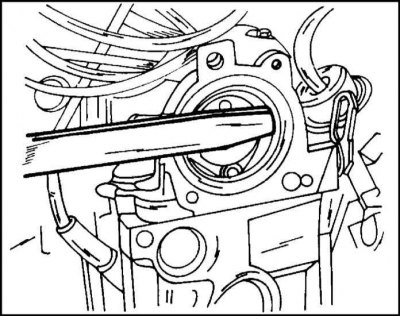

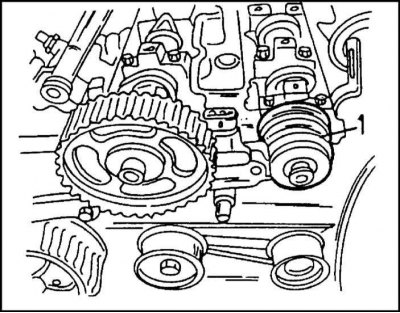

2. Install a wrench on the camshaft hex (located at the end of the shaft, see illustration.) and unscrew the camshaft wheel bolt with a wrench. Remove the wheel from the camshaft.

3. Screw a self-tapping screw into the stuffing box and pull it out with pliers from the cylinder head.

4. Liberally lubricate the outer and running surfaces of the new oil seal with grease and press it in with the pipe, washer and pulley bolt until it stops, as described above.

5. Install the wheel on the camshaft and screw in the mounting bolt. While holding the shaft from turning, tighten the bolt (1) on illustration torque 45 Nm.

6. Reinstall the removed parts, including the toothed belt. Bolts of fastening of a cover of the case of bearings of a camshaft tighten the moment of 8 Nm.

Replacement of an epiploon from outside a camshaft

1. Remove toothed belt (see related description).

2. Using a pry bar, press the oil seal out of the camshaft bearing housing as shown in the illustration. Be careful not to damage the housing.

3. Lubricate the new oil seal with grease and press it in. For pressing, you can use a plate fixed to the threaded holes.

Camshaft, camshaft bearing housing and components

The camshaft of the OHC engine is located in a separate housing. The engine in question has hydraulic valve lifters that maintain constant valve clearances. The camshaft, bearing housing, hydraulic pushers, rocker arms and oil seals can be removed independently of each other.

The camshaft bearing housing is removed as follows:

1. Remove the cylinder head (Chapter Cylinder head and valves).

2. Turn away bolts and remove a cover of a fixing plate of a camshaft.

3. Loosen the two bolts and remove the camshaft mounting plate (illustrations). Now you can remove the camshaft from the cylinder head. On the drive side of the shaft with a screwed-in screw, on the gearbox side according to fig.

If a new camshaft is to be installed, all rocker arms must be replaced.

If a used camshaft will be installed, it is necessary to check the degree of wear of its necks and cams. Measure the inner diameter of the bearings and the outer diameter of the crankshaft journals with a micrometer. Determine the gaps in the mate. If they are out of range, the camshaft and/or camshaft bearing housing is replaced.

Install the camshaft with the outer journals in the prisms or clamp in the centers of the lathe, and bring the measuring tip of the indicator to the central journal. Rotate the camshaft slowly and read the indicator. If it is more than 0.04 mm, the camshaft must be replaced.

Install the camshaft in place with the pressure plate. Fix the indicator at the end of the shaft and press its measuring tip against the end of the shaft. Move the camshaft back and forth as far as it will go and measure the end play. It should be 0.09–0.21 mm. If the clearance is out of specification, the pressure plate or, in extreme cases, the shaft itself must be replaced.

Check the flatness of the upper and lower planes of the camshaft bearing housing. In addition, the height of the hull must have a certain value, which allows grinding the planes in case of their deformation.

4. Insert the camshaft into the bearings, lubricating the journals with graphite grease. Be careful not to damage the bearings.

5. Insert the pressure plate into the grooves and tighten the mounting bolts to 8 Nm (see illus.).

6. Lubricate the seals with oil and carefully press them with a pipe on both sides of the body.

7. Install the cylinder head as described in the appropriate section for the OHC engine, taking into account design differences depending on the year of manufacture.

Hydraulic pushers

After removing the camshaft, the hydraulic tappets and rocker arms can be removed or replaced. These parts can be replaced without removing the camshaft. However, this requires a special tool to compress the valve spring, which will allow you to remove the pressure element and then remove the pusher.

DOHC engine

The engine has an automatic tensioner and toothed belt guides. A similar device has a C 20 NE engine. The toothed belt guides are made in the form of rollers. The belt laying diagram is shown in fig.

Removal and installation of gear wheels of a camshaft

1. Disconnect the ground cable from the battery.

2. Remove the toothed belt as described below.

3. Unscrew the bolts securing the cover of the ignition cables and disconnect the plug connection using the tool included in the kit.

4. Disconnect the 2 hoses from the cylinder head cover and disconnect the plug connection of the camshaft position sensor.

5. Remove the cylinder head cover. Pay attention to the presence of sealing rings.

6. Holding the camshaft by the hexagon wrench against turning, as shown in illustration. for a DOHC engine, remove the gear wheel mounting bolt. On this engine, the hexagon is located directly behind the camshaft wheel.

7. Remove the shaft wheels.

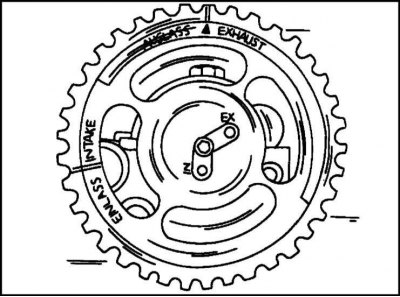

Installation of gears is carried out in accordance with illustr. The wheel has one hole marked "IN" and a second hole marked "EN". When installing wheels, keep the following in mind:

1. The intake camshaft pin must fit into the hole "IN" wheels.

2. The exhaust camshaft pin must fit into the hole "EX" wheels.

3. Screw in the wheel bolt. While holding the camshaft from turning, tighten the bolt to 50 Nm. From this position, tighten the bolt by an angle of 60±15°.

4. Turn a camshaft so that both labels shown on illustr. label (2) of each wheel, align with the ledge (1) on the front bearing cap.

5. Install the cylinder head cover with O-rings. Tighten the mounting bolts to 8 Nm.

6. Put on the toothed belt as described below.

7. Perform other work in the reverse order of removal. In particular, connect the crankcase suction hose, match the plug-in connections of the spark plugs, the camshaft position sensor, install the ignition cable cover.

Camshaft oil seal

1. The camshaft oil seal can be replaced after removing the wheel, in the same way as described above. A new oil seal is installed using a pipe, a wheel washer (1), as shown in illustration.

Toothed belt replacement

The layout of the toothed belt is shown in illustration. higher. To remove it, it is necessary to release the end part of the engine.

1. Disconnect the ground cable from the battery.

2. Mark the direction of rotation of the belt on the belt with paint and remove the belt as described in Chapter Cooling and heating systems.

3. Place the car on stands at the front.

4. Remove the shield under the car.

5. While holding the crankshaft pulley bolt as shown in the illustration, remove the vibration damper mounting bolts. Remove the damper.

6. Remove the cable guide from the toothed belt guard at the front of the engine. The belt laying diagram corresponds to illus.

7. The tensioner of the engine in question is similar to that of the OHC engine. First, set the crankshaft to TDC. Using a socket, turn the crankshaft in the direction of rotation so that the mark (1) coincided with the corresponding mark in the lower position (illustrations). At the same time, the marks on the camshaft wheels and on the bar behind the toothed belt must match, as described above.

8. Loosen the tension roller fixing bolt and turn the adjusting eccentric to the right in the direction of the arrow, as shown in the illustration, so that the pointer (1) stood opposite the left stop.

The belt is now loose and can be removed.

Instruction. If a belt is to be used, it must be prevented from contact with oil and grease and from bending. It is best to store the belt on the wall by hanging it with a nail.

9. Check that the camshaft and crankshaft are in the position shown in illustration. Otherwise, turn the shaft very slowly (s). The pistons may hit the valves. As soon as this is felt, turn the second shaft back. The coolant pump drive wheel should also be checked as it may not have turned correctly. The lug on the pump housing must match the corresponding projection on the cylinder block.

10. Put on a gear belt according to illustr. on gear wheels. The right side of the belt must be taut.

Now you need to tighten the belt. This work can also be done on the installed engine. This is done according to the maintenance plan after a certain mileage has been driven. To do this, it is necessary to provide access to the drive side of the distribution of the engine, where the adjusting eccentric is located.

Tensioning the toothed belt is carried out in the same way as the belt tensioning of the OCH 2.0l engine with a tensioner pulley.

11. Other work is performed in the reverse order of removal. The vibration damper is attached with a torque of 20 Nm. Establish a maple belt taking into account the direction of its rotation and tighten, as it is described in the Head Cooling and heating systems for this type of engine.

12. Install all removed parts.

Removal and installation of camshafts

Except for some differences, the removal and installation of the intake and exhaust camshafts is the same.

1. Remove toothed belt (see subsection "Removing the toothed belt"). Before removing the camshafts, the crankshaft must be installed in the position shown in the illustration, in which the angle between the lines is 60.

2. Remove the camshaft gears (see subsection "Removal and installation of camshafts").

3. Check that the markings on the camshaft covers are clearly visible. Otherwise, label the covers.

4. Loosen the cover bolts crosswise in a few turns (1–1.5 turns) so that the covers are free. Remove the covers in order and store them in the order they were installed. The front bearing is the guide.

5. Using a rubber suction cup, remove the hydraulic pushers.

6. Check the camshafts as described for the OHC engine.

Installation of camshafts is carried out as follows:

1. Lubricate the camshaft journals and the sliding surfaces of the hydraulic tappets with graphite grease. install shaft (s) into the bearings.

2. Lubricate the contact surface of the front bearing with sealant and install all bearing caps. Check immediately that the cap markings match.

3. Tighten the bearing cap bolts crosswise to 8 Nm.

4. Install a new oil seal as described above (illustrations).

5. Install the camshaft gears.

6. Turn the crankshaft in the direction of rotation with the socket head so that the marks match (1), as shown in illustration.

7. Install the toothed belt as already described for this engine.

Replacing the toothed belt tensioner

Tension roller is removed (fastening bolts are loosened) after removing the toothed belt.

1. When installing the tension roller, it is necessary to pay attention to the one shown in the illustration. locking lever (1). The lever must enter the pump guides (2). The tightening torque of the fastening bolt is 25 Nm. Finally, put on the toothed belt as described above.

Replacing the guide roller

1. One of the rollers is mounted on the holder, the other on the cylinder head. To remove the roller, you must remove the toothed belt. The roller mounting bolts are tightened with a torque of 25 Nm.

Engine 2.4 l (camshaft chain drive)

Removal and installation of the camshaft drive housing

These works were described above in the description of the removal of the crankshaft.

Replacing the drive chain and sprockets

The description of this work is given above in the description of the removal and installation of the crankshaft of this engine.

Distributor shaft drive gear

The gear is located at the end of the crankshaft. Its removal and installation are described in the description of work related to the camshaft drive. Work is carried out without removing the drive housing.

1. Remove the viscous fan (separate description).

2. Remove V-belt (separate description).

3. Remove the belt pulley.

4. Remove the gland from the hole in the actuator housing as described in the appropriate section.

5. Remove the distributor cap.

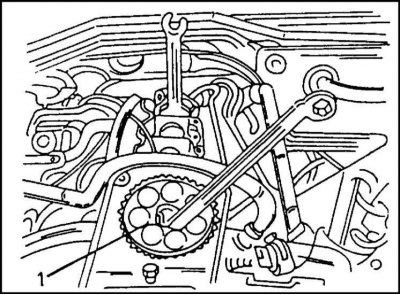

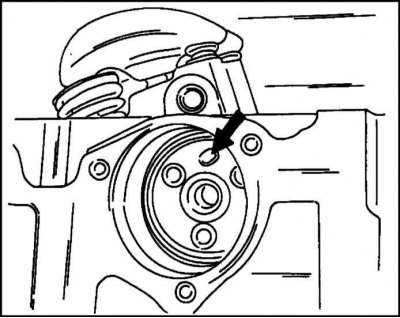

6. Turn the engine so that the piston of the first cylinder is at the TDC of the ignition moment. This can be determined by the slider. The slider must, as shown in the illustration, point to the groove in the edge of the distributor housing.

7. Remove the gear. Turn the distributor slider in the opposite direction of rotation. In this case, the gear can be removed. Sometimes she can eat. You can remove it with two hooks bent from a wire with a diameter of 3 mm. The ends of the wire are bent at a right angle at a distance of 5 mm. Grab the gear with the hooks as shown in the illustration.

The gear is installed as follows:

1. Install the gear on the crankshaft with the shoulder towards the shaft so that the slider is in the position shown in illustration.

2. Install the oil seal in the camshaft drive housing as described above.

3. Install the pulley on the crankshaft and put on the V-belt. Pull the belt (separate description).

4. Install the viscous coupling. Check the slider position first.

Removal and installation of a camshaft

1. Remove the cylinder head as directed.

2. Remove the camshaft rockers and remove the hydraulic pushers.

3. Turn away bolts and remove an assembly cover behind and side of a head of cylinders.

4. Remove the camshaft from the bearings, being careful not to damage the journals and cams of the bearings.

Instruction. When replacing the camshaft, pay attention to the markings on the end of the shaft. On illustration. marked location shown "U". In addition, the shaft is color-coded. The nominal size shaft is marked blue/brown. ground shaft (neck diameter is 0.1 mm smaller) has purple markings.

The camshaft is installed as follows:

1. Lubricate the necks and working surfaces of the cams and the top side of the hydraulic tappets with graphite grease.

2. Insert the camshaft from the front into the cylinder head. Rotate the shaft several times and install the covers.

3. Turn the camshaft so that the guide pin is in the position shown in illustration.

4. Install the hydraulic lifters. Put the used pushers in their places.

5. Install rockers.

6. Install the cylinder head in accordance with the instructions for this engine.

7. Adjust the hydraulic pushers, if they were removed. Adjustment requires care.

- Set the piston of the adjustable cylinder to TDC.

- Loosen the adjusting nut as shown in the illustration so that there is no play in the valve.

- Tighten the adjusting nut so that there is no gap between the valve, rocker arm and pushrod.

- From this position, tighten the adjusting nut one full turn.

Adjustment occurs in the order of ignition. After removing the cover of the ignition distributor, according to the position of the slider (illustrations) You can determine which piston is at TDC. The sequence of adjustment can be any. It is only necessary that the adjustment be carried out on a certain cylinder corresponding to the piston position and stroke.

Instruction. The hydraulic tappets can be adjusted while the engine is running.

This is done as follows:

8. Warm up the engine to operating temperature.

9. Remove the cylinder head cover and mudguard.

10. Install the socket, as shown in the illustration, on the rocker of the first cylinder and loosen the adjusting nut so that the rocker begins to click.

11. Tighten the adjusting nut again until the noise stops.

12. Tighten the adjusting screw another quarter turn and wait about 10 seconds until the engine starts to run normally. Turn the adjusting screw an additional 3 turns.

Replacing camshaft bearings

The camshaft bearing bushings located in the cylinder head can be replaced. If the bushings are worn, they are pressed out and replaced.

This operation is best performed in a car repair shop, because. it requires the use of special equipment.

Visitor comments