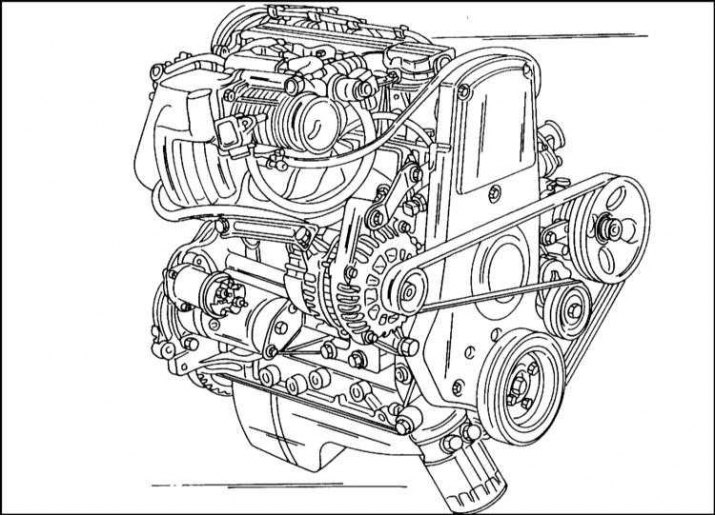

View of the 2.0L engine from the suction side

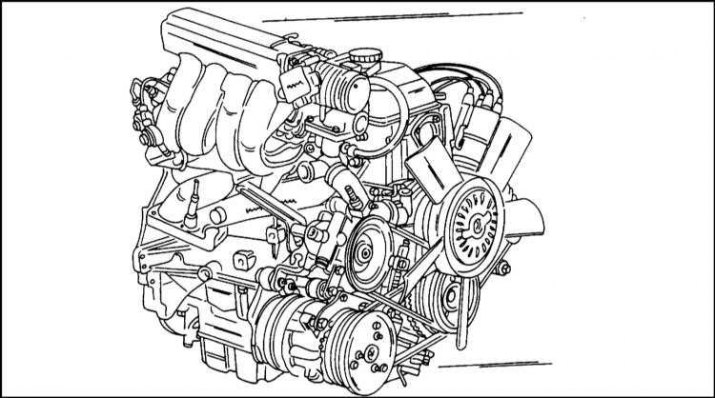

Engine type 2.4 l (From 24 NE). The engine has a camshaft chain drive

Before starting work, thoroughly clean all external surfaces of the engine. All openings on the engine must first be covered with a clean cloth to prevent dirt or other foreign particles from getting inside

The disassembly of individual engine components is described in detail further in the subsections under the heading "Repair".

This describes the work carried out on the engine installed on the vehicle or on the removed engine. If it is necessary to carry out a complete disassembly, then the individual operations should be combined with each other in the sequence indicated.

The description means that the cylinder block is replaced, although this is not always necessary. References are constantly given to sections where the work is described in more detail.

Before disassembly, all moving and sliding parts must be marked so that they can be reinstalled if they are to be reused. This applies in particular to pistons, valves, caps and bearing shells. Engine parts should be stored so that they do not need to be carried over each other.

Do not mark bearing surfaces or sealing surfaces with any sharp objects such as a scriber or by impact. Needs to be marked with paint. Valves are best stored by poking them through an upside down cardboard box. At the same time, its number is written next to the valve. If the engine has a multi-valve distribution of each cylinder, then the valves belonging to one cylinder must be separated from the other valves.

Aluminum alloy parts require appropriate handling. If their disassembly requires striking with a hammer, then the hammer must be rubber or leather. If the required stand is not available, appropriate wooden stands should be used. The stands must be such as to provide access to the top and bottom of the engine. If a mounting stand is used, the exhaust manifold is disconnected from the engine and the engine is bolted to the stand.

The cylinder head, after it has been removed from the engine, can be secured in a vice with a metal clamp screwed to the intake manifold studs.

A complete disassembly of the engine is not described, since it is done only in rare cases. A description of the removal of individual engine components is given in the relevant sections. The cylinder head can be removed without removing the engine.

The timing belt and thus the timing chain can be replaced without removing the engine.

The following work can be carried out without removing the engine:

Engine 2.0 l (timing belt driven distribution mechanism)

- Replacing the rear crankshaft seal.

- Replacing the front crankshaft oil seal (in the oil pump housing).

- Replacing the oil seal in the camshaft housing on the gearbox side.

- Replacing the oil seal in the camshaft housing on the drive side of the distribution mechanism.

- Removal and installation of the camshaft, camshaft housing, rocker arms and valve clearance compensator.

- Removal and installation of a head of cylinders.

- Removal and installation of the oil pan.

- Removal and installation of the oil pump.

- Removal and installation of connecting rod and piston group.

- Removal and installation of the flywheel.

Engine 2.4 l (chain driven distribution mechanism)

- Replacing the intake manifold and exhaust manifold gaskets.

- Replacing the rear crankshaft seal.

- Replacing the oil pan gasket.

- Replacing the gasket in the front of the crankshaft (timing case).

- Removal and installation of the flywheel.

- Removal and installation of the camshaft and camshaft bearings.

- Removal and installation of rocker fingers.

- Removal and installation of valve stem seals.

- Removal and installation of a head of cylinders.

DOHC engine

- Replacement parts of the distribution mechanism (V-belt, tension roller), camshaft gears, camshaft oil seals, toothed belt, toothed belt guide roller.

- Removal and installation of a head of cylinders.

- Removal and installation of the flywheel.

Only fairly large works are listed here. In addition, there are many smaller jobs that can be done without removing the engine.

The engine must be removed for the following procedures:

- Removal and installation of the crankshaft or replacement of crankshaft bearings (new crankshaft installation).

- Replacement of a back epiploon of a cranked shaft (depending on engine type).

Visitor comments