Removing

1. Disconnect the ground cable and positive cable from the battery.

2. Remove the hood. Place the hood in a vertical position beforehand and disconnect the fluid supply hose to the washer nozzles. Use a pencil to trace the hinges on the surface of the steel sheet of the hood so that you can put the hood back in its original position later. Loosen the hinge screws. In this case, the assistant must hold the hood. Remove the hood and put it in a well protected place. Place a thick cloth under the edges of the hood.

3. Drain the liquid from the cooling system (Chapter Filling the cooling system cooler Chapters Ongoing care and maintenance) and plug the system hoses. These include the three radiator hoses, the hose between the coolant expansion tank and the coolant supply pipe at the suction pipe, the coolant return hose from the suction pipe, and the water supply and return hoses to the heater.

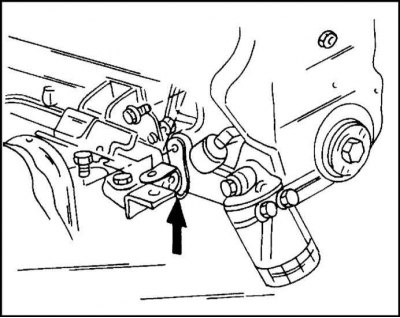

4. Disconnect the ground cable from the engine battery at the point shown in illustration. The arrow points to the connection point of the motor ground cable.

5. Disconnect the cable harness from the engine. It is fixed in several places: in the multi-position plug and socket on the wall of the engine compartment, in the multi-position plug and socket at the engine wiring branch on the front right, at the fuse box, at the temperature sensor, at the air mass meter and at the oxygen sensor. It is recommended to mark the connections to facilitate their further assembly.

6. Remove the heatsink and cooling fan as described in the appropriate section.

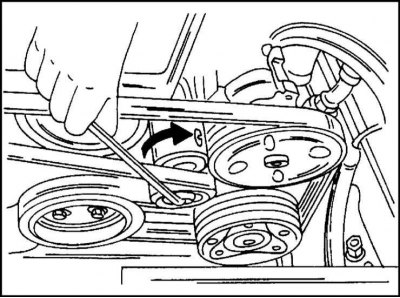

7. Put an arrow on an easily accessible place on the V-belt to indicate the direction of rotation of the V-belt. Turn the belt tensioner as shown in the illustration in the direction of the arrow so that the belt is loosened and remove it.

8. Remove the power steering pump. To do this, unscrew the bolt from the console and the pump bolts. Remove the pump and tie it on a wire to any structural element. Do not open the hydraulic system, do not hang the pump on hoses.

9. If you have an air conditioner, remove the compressor. To do this, disconnect the compressor bracket from the cylinder block and the console of the unit. Fastening is carried out by three bolts in front and four behind.

10. Release the throttle cable from the holder and remove.

11. Disconnect the vacuum hose from the suction pipe.

12. Disconnect both fuel lines at the end connections.

Attention! When opening a pipeline under pressure, fuel is ejected. Never place a control lamp near. When opening the connection, it is recommended to put a wrench on it and cover it with a rag on top. After that, slowly unscrew the hollow bolt.

13. Unscrew the oil hose connection from the oil filter head. Pay attention to the presence of the sealing ring.

14. Disconnect the two coolant hoses from the throttle body. Disconnect also the vacuum hose going to the evaporator control valve.

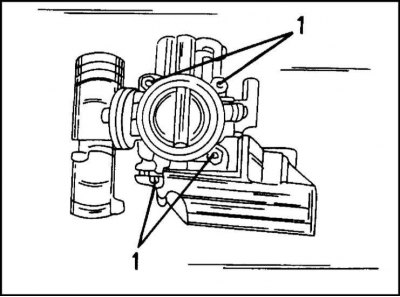

15. Loosen the four mounting screws (1), shown in the illustration and remove the throttle body and intake manifold.

16. Now disconnect the cable at the end of the ball head. The cable is attached to the support with a spring clip, which must be removed. After releasing the clamp, the cable can be disconnected.

17. Turn away a cap nut and disconnect a vacuum hose of the brake booster from the inlet pipeline.

18. If present, remove the bottom protective sheet from the bottom (put the car on stands).

19. Dock from the underside of the car (put the car on stands) connector for the oxygen sensor. Remove the bolts securing the exhaust system brackets and remove the exhaust pipe with the catalytic converter from the muffler.

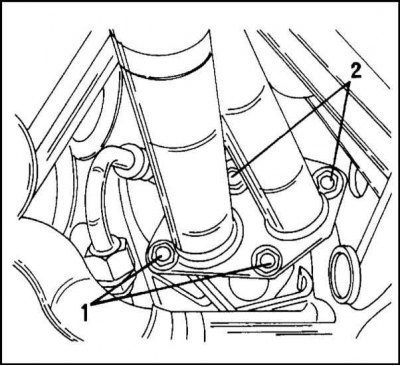

20. Turn away bolts (1) And (2), shown in illustration. and disconnect the downpipe of the exhaust system, with the catalytic converter attached to it, from the exhaust manifold. Lower the entire assembly down and out.

21. Disconnect the coolant hose from the pipeline.

22. Remove the gearbox and transfer case as described in the appropriate section. After that, only one engine remains on the suspensions.

23. Attach hoist cables or chains to the engine lugs and raise the engine. Remove the suspension and lift the engine up, separating it from the suspensions. Be careful not to damage any cable connection or piping, or hit the engine against anything in the engine compartment. The operation is recommended to be performed with an assistant.

Installation

The engine is installed in the reverse order of removal. Most of the instructions for installing an OHC engine also apply to a DOHC engine. The fuel lines are fastened with a torque of 15 Nm. In this case, it is necessary to hold the nipple with a wrench from damage by the tightening torque.

Visitor comments