The following description of some of the works is given in brief form. For their implementation, special knowledge is required. Describes the work to replace some parts.

The injection system works in conjunction with static ignition and a knock sensor. The electronic control unit regulates the composition of the mixture and ignition.

The amount of injected fuel depends on the duration of the opening of the injection valve. Injection duration depends on engine load (pressure meter), engine speed (flywheel sensor) and other engine condition factors.

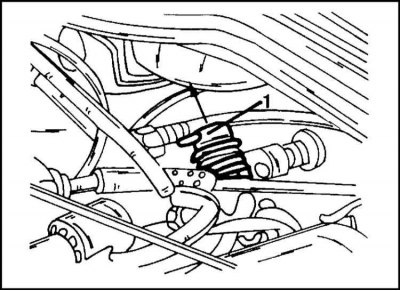

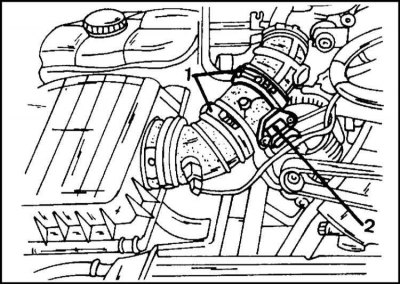

Throttle Potentiometer

Seen from the front, the potentiometer (1) located on the left wall of the engine compartment, to the right of the shock absorber. To remove it, disconnect the plug connection and, having unscrewed the fastening bolts (illustrations).

Before installation, attach the throttle valve. Check that the potentiometer is properly seated on the throttle shaft. Connect the plug connection.

Fuel pressure control

1. The fuel system pressure must be relieved following the above precautions.

2. Disconnect the vacuum hose from the pressure regulator and remove the clamp from the pressure regulator and fuel distribution line. The pressure regulator is located on the back of the engine.

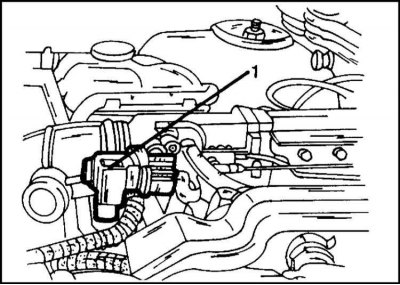

3. Check how the fuel pressure regulator is installed (1) and remove it from the top of the fuel distribution line, as shown in illustration. O-rings are located on the pressure regulator.

4. Before installing the regulator, lubricate the sealing rings with engine oil and insert the regulator into the fuel distribution line so that it takes its original position. Fasten the regulator and put on the vacuum hose.

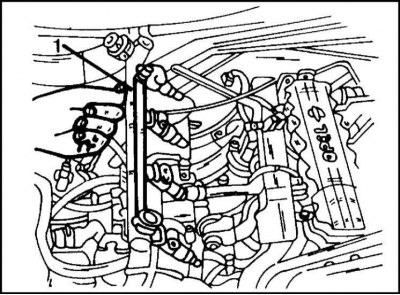

Replacing injection valves (injectors)

1. Relieve system pressure.

2. Disconnect the fuel lines in places (1) And (2), as shown in illustration.

3. Disconnect the acceleration actuator from the throttle body. Detach the support from the intake manifold and set aside.

4. Disconnect the two vacuum hoses, one from the intake manifold and the other from the fuel pressure regulator.

5. Remove a fixing pin at a fuel distributive highway. It is not immediately visible and is located next to the throttle body.

6. Disconnect the plug connection of the injection valves.

7. Turn away a nut of a cable of weight from a bolt of fastening and remove a cable. Turn away a bolt of fastening of a fuel distributive highway.

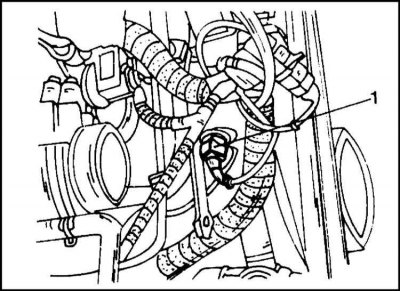

8. Remove the fuel distribution line (1) together with injection valves (illustrations). Remove the clip to replace the injection valve.

Installation is carried out in the reverse order of removal. The fuel distribution line is fastened with a torque of 8 Nm, the ground cable with a torque of 7 Nm. Reconnect the fuel lines. Attach the throttle support with two bolts.

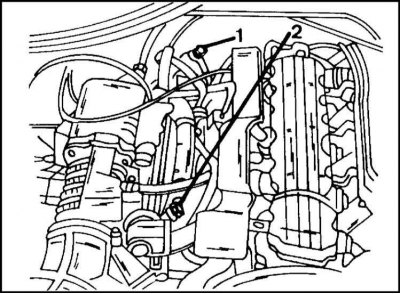

Replacing the air quantity meter

The air quantity meter is located directly in front of the air filter and is inserted into the suction hose.

1. Remove clamps (1) and plug (2) on illustration

2. Remove the air quantity meter from the suction hose. If there is external damage, it must be replaced. The meter has an arrow indicating the direction of air flow. The hoses must be connected tightly.

Replacing the crankshaft TDC sensor

Contact the Head Engine electrical equipment.

Replacing the knock sensor

Contact the Head Engine electrical equipment.

Oxygen sensor replacement

1. The oxygen sensor is located in the exhaust pipe of the muffler and can be turned out after disconnecting the plug (at the gearbox) connections. Before installing the sensor, the connecting thread must be lubricated with special grease. The sensor is tightened with a torque of 30 Nm. Make sure that the sensor wires do not adjoin the exhaust pipe of the muffler and cannot be rubbed against the elements of the vehicle chassis.

Idle speed controller

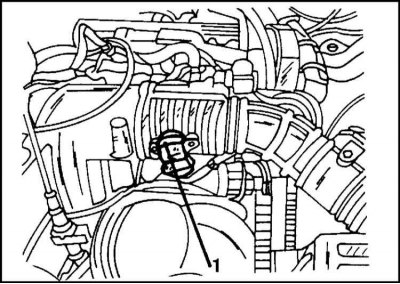

1. idle speed controller (1) located in the location shown in the illustration on the throttle body and is secured with two bolts. Disconnect the plug before removing. The regulator has a seal that must be installed correctly.

Intake air temperature sensor

1. The sensor is screwed into the intake air hose near the air filter inlet.

After disconnecting the plug connection and removing the intake air hose, the sensor can be pressed out with a sharp object (like a knife) from a hose. Before installing the sensor in place, check the condition of the hose. Reinstall all removed parts.

Coolant temperature sensor

1. Replacing this sensor is quite laborious, since access to it is not convenient. It is screwed into the thermostat housing (illustrations). To get to the sensor (1), it is necessary to remove the V-belt and alternator (push aside), disconnect the plug connections on the air intake hose, the air intake hose between the air filter housing and the throttle body and the temperature sensor. Then unscrew the sensor. The new sensor is fastened with a torque of 8 Nm. Removed parts are installed in reverse order.

Visitor comments