Clutch Release Bearing

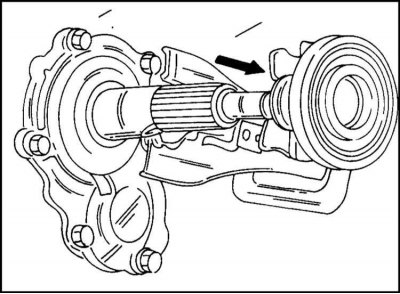

The clutch release bearing can only be removed and installed with the gearbox removed. The bearing is attached to the housing with spring clamps. After removing the clips, remove the pin and lever. Remove the bearing from the gearbox housing as shown in illustration.

Press the bearing out of the housing. Disconnect the lever pin from the gearbox shaft cover.

Press on new bearing. When doing so, make sure that the thrust side of the bearing points away from the housing. Install the clutch release lever pin on the cover.

Lubricate the inner bore of the bearing housing, the bushing in the gearbox shaft cover, and the ball pin of the lever with grease. Reinstall bearing, clutch release lever and rubber boot. Pay attention to the correct position of the clips on the lever behind the ball stud.

Clutch slave cylinder

Installation and removal of the hydraulic cylinder is carried out as follows.

1. Pour fluid into the reservoir of the main hydraulic cylinder up to the top edge. Close the hole with polyethylene and screw on the plug. Thus, liquid leakage from the cylinder is excluded. If it is necessary to pour liquid from the system, then proceed as follows:

2. Attach the hose to the bleed valve on the working cylinder. Lower the other end of the hose into a container, and unscrew the fitting a few turns. With the help of an assistant, press the pedal so that all the liquid comes out.

3. Loosen the hollow hose bolt and remove the sealing washers.

4. Turn away two bolts and take out the cylinder.

Installation of the cylinder is carried out in the reverse order of its removal. In doing so, you need to pay attention to the following:

1. Tighten the cylinder mounting bolts for the MSG gearbox to a torque of 28 Nm. with a MUA box with a torque of 45 Nm.

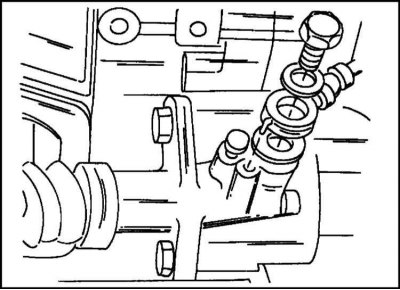

2. Tighten the swivel bolt with two new O-rings (illustrations). The correct position of the hose ring is ensured by a pin. Bolt tightening torque 35 Nm.

3. Bleed the hydraulic system and adjust the clutch pedal height as described below.

Repair of the working hydraulic cylinder

During repair, the hydraulic cylinder is replaced with a repair kit. Such a defect as corrosion of the outer surface is the basis for replacing the cylinder.

When assembling the inner parts of the cylinder (except for protective caps) lubricated with brake grease.

When installing the caps, check the ease of movement of the piston.

Clutch damping cylinder

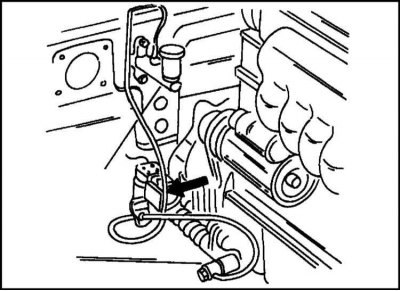

1. The clutch damping cylinder is located in the location shown in fig. Before removing the damping cylinder, close the reservoir or drain the system as described above. To do this, disconnect the hoses from the cylinder and unscrew the holder nuts.

2. When installing, tighten the bolts to a torque of 8 Nm. Tighten hose connections to 20 Nm.

3. After installation, remove air from the system and check the fluid level in the tank, add fluid if necessary.

Removal and installation of the main hydraulic cylinder

To remove the main hydraulic cylinder, the clutch pedal and holder are removed. The cylinder is removed as follows:

1. Drain the system as described above or suck the fluid out of the reservoir.

2. Disconnect the hose from the cylinder. Make sure that the leaking liquid does not get on other parts.

3. Remove the clutch pedal and bearing support.

4. Loosen the two nuts and remove the cylinder.

5. Installation of the main cylinder is carried out in the reverse order of removal. Tighten the cylinder mounting nuts to a torque of 15 Nm. Finally, bleed the system and check the fluid level in the reservoir. Add fluid if necessary.

Repair of the main hydraulic cylinder

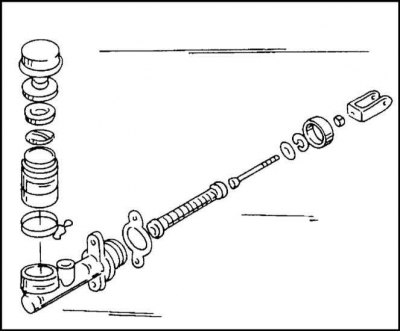

1. If a repair kit is available, the hydraulic cylinder is repaired in a known manner. Unscrew the stem with a fork (lock-nut) and measure between the center of the finger hole and the mating surface of the cylinder body (size write down). This dimension will be required later during assembly. If, during disassembly of the cylinder, traces of corrosion or any other defects are found on its working surface (bullies, etc.), the cylinder is replaced. The disassembled cylinder is shown in fig.

2. By disconnecting the hose clamp, you can remove the tank from the cylinder.

All internal parts are lubricated with brake fluid or grease (except for protective cap). When assembling the cylinder, keep the previously recorded dimension and tighten the locknut. Check the free movement of the piston.

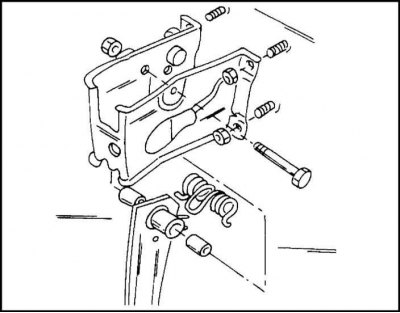

Clutch pedal and bearing support

The operation is quite laborious.

1. Remove the lower facing of the panel of devices from outside the driver.

2. Remove the air duct from the driver's side.

3. Remove the spring clip at the junction of the main hydraulic cylinder rod and the clutch pedal. Remove the support pin and disconnect the fork from the pedal.

4. Remove the four bolts and remove the bearing support. After removing the pedal support pin, the pedal and return spring can be removed. Pay attention to the spring attachment.

5. Loosen the pedal stop bolt and locknut.

6. Installation of the parts in question is carried out in the reverse order of removal. Attachment details are shown in fig. Check that the return spring is correctly attached to the pedal and to the bearing support. The pedal pin nut is tightened to 35 Nm, the bearing support nuts to 21 Nm.

Finally, adjust the pedal height and travel as described below.

Visitor comments