1. Mark the position of the clutch in relation to the flywheel. This can be done with a center punch by marking the edges of the flywheel and clutch.

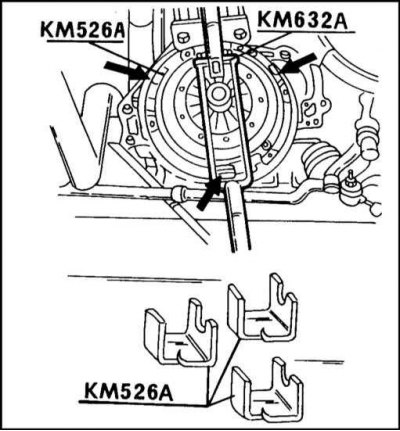

2. After that, the pressure spring is compressed. In car repair shops, a lever is used for this purpose, as shown in the illustration. The lever is attached with two M12x30 bolts to the upper side. If you now press the lever on the clutch from below, the pressure spring is compressed, as happens when the clutch is turned off. If you observe the installation sites of the rotating bearings, indicated by arrows in the illustration, you will notice that the pressure plate moves away, leaving some space behind. Steel brackets must be inserted into the resulting gap (attachment KM-526-A), shown in the illustration below. If the lever is released, the plates are clamped. In this position, you can unscrew the clutch mounting bolts. In the absence of the above device, the spring can be compressed in some other way.

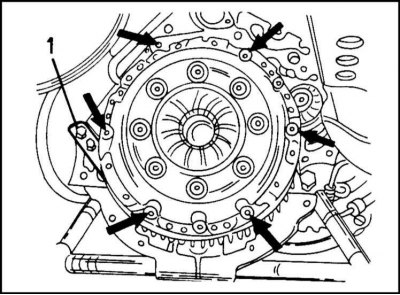

3. Loosen the six clutch mounting bolts evenly in a diagonal pattern and remove the clutch. In doing so, the flywheel must be adequately restrained from turning. To do this, a sufficiently strong screwdriver can be inserted between the teeth of the ring gear, or a flywheel stopper can be used, as shown in illustration.

4. Remove the clutch and take out the driven disc. One side of the driven plate is marked as the gearbox side. Keep this in mind when installing the disc.

5. Wipe the inside of the flywheel with a rag (blowing with compressed air is not allowed) and check the friction surface of the flywheel. If the driven plate is worn down to the rivet heads, the rivets may leave marks on the flywheel or pressure plate surfaces.

6. If a new clutch basket is installed, the steel clips must be transferred to it. Now it's easier. Place the clutch on the friction surface and press the compression spring down with the heel in the center (taking the necessary precautions). Take out the staples. Install the brackets under the pivot points.

If it is necessary to disconnect the gearbox from the engine, loosen the clutch mounting bolts so that the clutch can be controlled.

Visitor comments