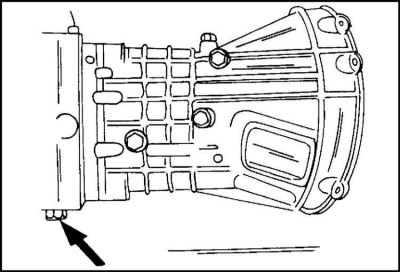

Drain plug for MSG gearbox. The plug serves to drain the oil from the gearbox and transfer case.

Removing

Before removing the gearbox, it is necessary to carry out some preparatory work, described below. It is necessary to remove the shift and gear selector levers, as well as the shift gate.

1. Raise and place the car on stands.

2. Remove the drain plug from the crankcase.

3. Drain the oil into a container.

4. Turn away four bolts.

5. Remove the shield under the transfer case.

6. At the car till 1997 of release disconnect a flexible shaft of a drive of a speedometer.

7. For a car after 1997 release, disconnect the plug connection of the speedometer drive. The exception is cars with ABS.

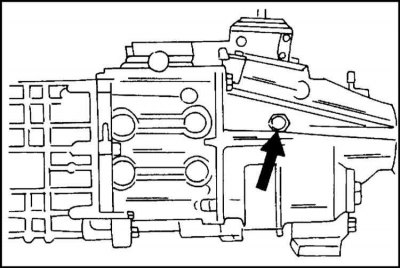

8. Disconnect the reversing light switch and engine control switch wires.

9. Disconnect a wire of a control lamp of inclusion of a full drive.

10. Remove the front and rear driveshafts as described in the appropriate section.

11. Remove both bolts securing the clutch slave cylinder.

12. Remove the cylinder. Set it aside.

13. Move a garage lift under the gearbox (if necessary, place a wooden block).

14. Raise the gearbox so that the cross member is unloaded.

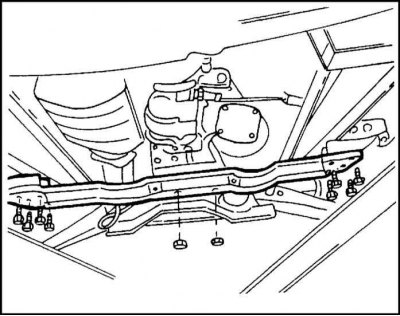

15. Turn away bolts.

16. Remove the muffler clamp from the cross member.

17. Loosen the nuts securing the gearbox bracket to the center of the cross member.

18. Remove the four bolts on the left and right sides of the cross member where it is attached to the stringer. The fastening of the cross member to the gearbox is shown in the illustration.

19. Turn away connecting bolts between the engine and a transmission.

20. Carefully separate the engine from the gearbox. Make sure that the gearbox does not fall off the jack. To do this, you need to use the help of an assistant. Keep in mind that the gearbox is heavy.

Installation

The gearbox is installed as follows:

1. Thoroughly clean the mating surfaces of the gearbox and engine.

2. Also check that the clutch release bearing, input shaft spline and cover sleeve are thoroughly cleaned.

3. If there is any doubt about the serviceability of the bearing, it must be replaced. The same applies to the clutch if it had defects in operation before removal.

4. Lubricate all sliding and rotating surfaces with multipurpose grease.

5. Engage a gear to facilitate engagement with the clutch disc.

6. Raise the gearbox with a garage jack and bring it to the engine.

7. Insert the gearbox input shaft into the clutch disc.

8. If the connection cannot be achieved immediately, it is necessary to turn the shaft flange back and forth several times so that the shaft engages.

9. Fully press the gearbox against the engine. In this case, the two pins on the cylinder block must enter the corresponding holes in the gearbox.

10. After the gap between the engine and gearbox flanges is selected, screw in the mounting bolts and evenly tighten to 70 Nm for the engine until the middle of 1995 of release.

11. For later engines, there are two sizes of bolts: large, tighten to 68 Nm and small, tighten to 41 Nm. Leave the garage jack under the gearbox.

12. Install cross bar and secure.

13. Bolts in the middle tighten to 48 Nm, bolts on the outside to 80 Nm.

14. Lower the garage lift and roll it out.

15. Install the clutch cylinder bolts.

16. Tighten to 28 Nm.

17. Carry out other work in the reverse order of removal.

18. Installation of the cardan shaft is described in the corresponding section.

19. The tightening torque for the transfer box shield is 47 Nm.

20. Finally, add oil to the gearbox.

21. Install the shift and select levers as described below. The same applies to the shift gate.

Visitor comments