17YD 1.7L engine

Loosen the clutch housing cover bolts.

Remove the top toothed belt cover.

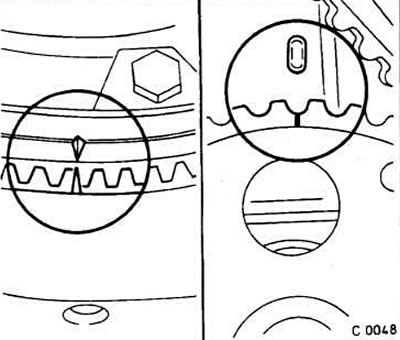

Set the piston of the 1st cylinder to TDC. To do this, turn the crankshaft until the TDC mark on the flywheel coincides with the tide on the clutch housing cover (see fig. left). In this case, the valves of the 4th cylinder should overlap (the mark on the gear pulley of the injection pump should be opposite the mark on its bracket (see fig. on right). To facilitate turning the crankshaft, engage 4th gear, jack up any of the front wheels and rotate it by hand.

Unscrew the central screw plug on the injection pump.

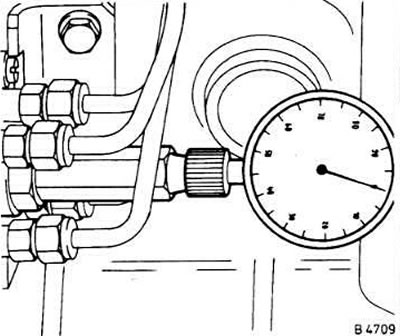

Replace the screw plug with an adapter (for example, Opel KM-226) and a small indicator (with measuring range up to 3 mm) with copper sealing washer.

Slowly turn the crankshaft against the operating direction of rotation (counterclock-wise) approximately 5 cm.

Set indicator to "ABOUT".

Rotate the crankshaft in the direction of rotation (clockwise) so that the TDC mark on the flywheel matches the corresponding mark on the engine block. In this case, the indicator leg should move by 0.9±0.05 mm.

Attention! If the TDC mark is accidentally missed, turn the crankshaft back and re-set the TDC.

If the above value is not obtained, it is necessary to adjust the position of the injection pump.

Set the piston of the 1st cylinder to TDC by turning the crankshaft in the working direction of rotation.

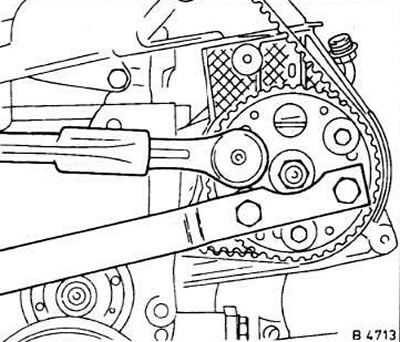

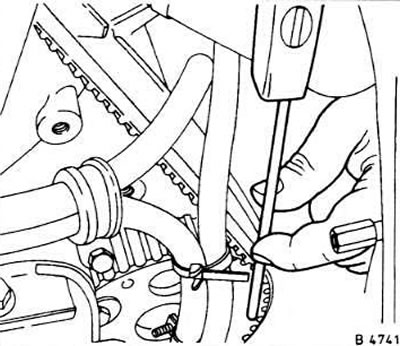

Loosen the bolts securing the injection pump toothed pulley. In Opel repair shops, a special tool KM-468 is used to keep the pulley from turning. You can also use a suitable chain wrench.

Set the preset advance value. To do this, slightly turn the injection pump by the housing. In repair shops, the Opel KM-541 device is used for this purpose. You can also use a regular screwdriver.

Lightly tighten the injection pump pulley bolts.

Check the adjustment again.

After the appropriate adjustment, finally tighten the pulley mounting bolts to a torque of 22 Nm, holding the pulley from turning with the Opel KM-468 tool. Remove indicator.

Screw the central screw plug back in place with a new copper washer and tighten the plug to 15 Nm.

Install and secure the clutch housing cover.

Install and secure the timing belt top cover.

Start the engine and wait a while for air to bleed from the fuel system.

After the test drive, check the tightness of the central screw plug and tighten if necessary.

TC4EE1 1.7L turbocharged engine

Disconnect wire "masses" from the battery.

Attention! This erases all information in the computer's memory.

Mark all hoses and other connections on the intake manifold with adhesive tape and disconnect.

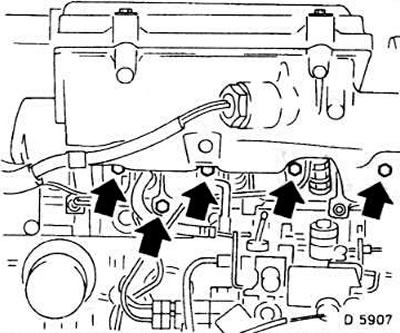

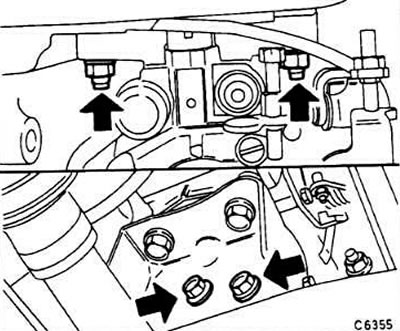

Loosen the bolts (see arrows in fig.) intake manifold mounts.

Loosen the two outer nuts on the intake manifold and remove it along with the air filter.

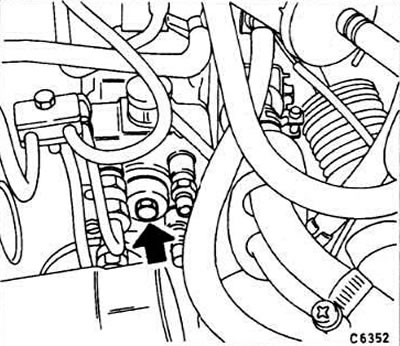

Unscrew the screw plug from the injection pump housing (see fig. C6352).

Disconnect the high pressure fuel lines by unscrewing their union nuts with a Hazet 612-17x19 ring wrench.

Attention! Do not bend pipes!

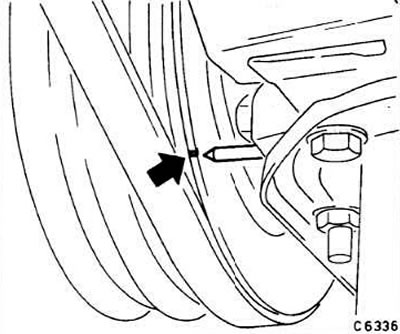

Set the piston of the 1st cylinder to TDC by turning the crankshaft so that the TDC mark on the pulley coincides with the pointer on the engine block (see fig.).

To facilitate the rotation of the crankshaft, engage 4th or 5th gear, lift any of the front wheels and rotate it by hand.

Using a screwdriver, disconnect the engine cold start device.

In place of the screw plug, screw in the Opel KM-226-A adapter and a small indicator (with measuring range up to 3 mm).

Set the indicator so that the minimum stroke of the measuring leg is 1 mm.

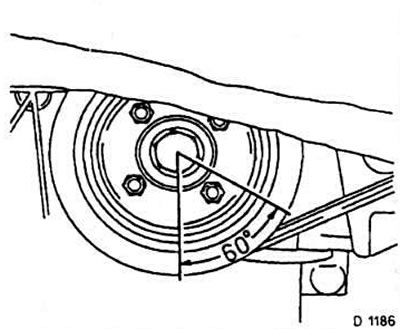

Turn the crankshaft in the opposite direction of the working direction of rotation (counterclock-wise) 60°to bring the injection pump pistons into position. In this case, the indicator needle should deviate minimally. In this position, set the indicator to zero. Rotate the crankshaft back and forth to check for proper adjustment. In this case, the indicator should not show a value less than 0 (see fig.).

Restore the original position of the crankshaft by turning it 60°back (clockwise) at TDC, and take a reading from the indicator (stroke of the injection pump plunger). It should be in the range of 0.5-0.6 mm.

If the value obtained is not within the specified range, adjust the position of the injection pump.

Loosen the injection pump mounting bolts (see arrows in fig.).

Rotate the pump until the set stroke of its plunger is reached. If the stroke exceeds the upper limit of the above range, then it is necessary to turn the pump towards the motor, and if it is less than the lower limit of the range, in the opposite direction. Recommended travel value (to strive for) - 0.55 mm.

After adjusting the position of the injection pump, tighten the bolts of its fastening. The tightening torque of the pump-to-cylinder head bolts is 25 Nm, and the pump bracket bolts are 40 Nm.

Remove indicator.

Screw in the central screw plug and tighten it to 20 Nm with a new washer.

Remove the screwdriver from the starter.

Reconnect the pipes and tighten their cap nuts to 25 Nm.

Clean the mating surfaces of the intake manifold and cylinder head of gasket residue using a triangular file. Install a new gasket.

Install intake manifold and tighten bolts and nuts to 30 Nm.

Connect all hoses and other connections to the intake manifold as marked.

Visitor comments