Signs of bad injectors:

- lack of ignition;

- knocking in one or more cylinders;

- engine overheating;

- drop in engine power;

- increased fuel consumption.

17YD 1.7L engine

Removing

Clean the nozzle lines.

Disconnect pipelines; Loosen the cap nuts with a slotted spanner, eg Hazet 612-17x19.

Attention! Do not bend pipes!

Disconnect drain lines.

Unscrew the injectors using a 27 mm socket wrench, e.g. Hazet 450.

Remove the shaped washer, heat shield and copper sealing washers.

Installation

Install a new sealing washer under the injector.

Install the heat shield so that its smaller diameter faces the cylinder head, i.e. down.

Install an additional copper sealing washer on the heat shield sleeve.

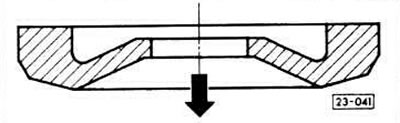

Insert a new shaped washer into the heat-shielding sleeve with the recess upwards (the arrow in fig.23-041 points to the cylinder head).

Screw in nozzles and tighten to 70 Nm.

Tighten injector lines to 25 Nm.

TC4EE1 1.7L turbocharged engine

Removing

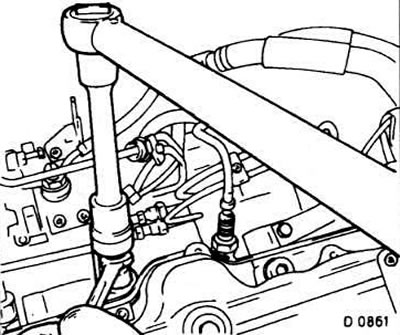

Remove intake manifold. Disconnect the high pressure lines by unscrewing the union nuts with a socket wrench, eg Hazet 612-17x19.

Attention! Do not bend pipes!

Loosen the drain pipe locknuts and remove it.

Unscrew the nozzles using a special key Opel KM-728.

Remove the shaped and sealing washers.

Installation

Place a new seal and a new shaped washer on the nozzle hole.

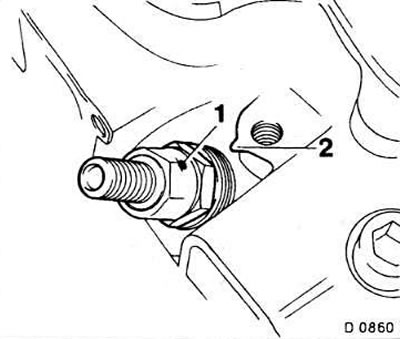

Insert the nozzle into the hole so that mark 1 (see fig. D0860) on the injector coincided with mark 2 on the cylinder head.

Tighten the injector clamps using a special Opel KM-728 wrench to a torque of 50 Nm. At the same time, hold the nozzle with a wrench.

Attention! The nozzle must not be rotated. The marks on the injector and cylinder head must match.

Install new gaskets on the drain pipe and tighten to 35 Nm.

Connect pipes and tighten union nuts to 25 Nm.

Replace the gaskets on the inlet pipes and tighten the screws securing the pipes to 30 Nm.

Visitor comments