Gasoline engines and 1.7L diesel engines

For 1.8 and 2.0 liter engines, the toothed belt tension must be checked every 60,000 km or every 4th service.

Attention! On 16-valve engines, the belt can not be adjusted. If the toothed belt was removed, then it must be replaced with a new one.

Attention! Since June 1990, all 1.4 and 1.6 liter engines are equipped with an automatic toothed belt tensioner. These engines can be identified by the flat toothed belt cover above the camshaft pulley and an additional idler pulley mounting bolt above the crankshaft. The automatic tensioner requires no maintenance or adjustment. Adjustment is required only when the toothed belt is removed and reinstalled.

Examination

To check the tension of the toothed belt, a special device Opel KM-510-A is required. To turn the coolant pump when the toothed belt is tensioned, the following Opel wrenches are required:

- for engines with a volume of 1.4 and 1.6 liters - KM-412A;

- for engines with a volume of 1.8 and 2.0 liters - KM-637;

- for diesel engines - KM-509.

You can use the usual standard keys, but you will have to first remove the generator.

Proper tension greatly affects belt life. Tension should be checked when the engine is warm (the engine is considered warm if the coolant temperature is about 80°C). A new belt is recommended to be installed and tensioned on a cold engine (at engine temperature below +25°С).

Attention! The toothed belt must not be broken or twisted by hand. Incorrect tension causes noise during its operation.

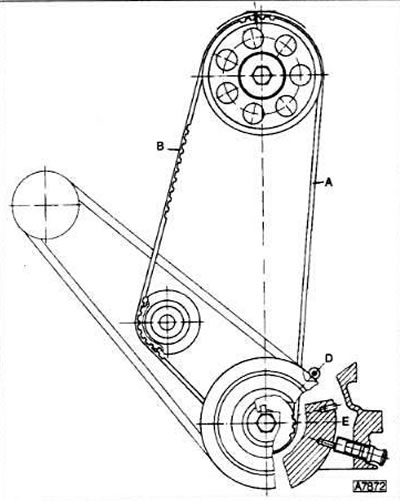

Belt tension is checked on branch B (fig.A7872). A tension checker is installed at the top of the belt.

Loosen the alternator tensioner and remove the V-belt. Tilt the generator down.

Remove the front toothed belt cover.

Check toothed belt for cracks and fraying. If necessary, replace the belt with a new one.

Rotate the engine crankshaft in the direction of rotation by at least 90°to tension the toothed belt. The first cylinder must be at TDC.

Install the tensioner KM-510A at point B of the toothed belt (see fig.A7872). Slowly remove the stopper from the device. With a slight pressure of the fingers in the device, the fixation is turned off.

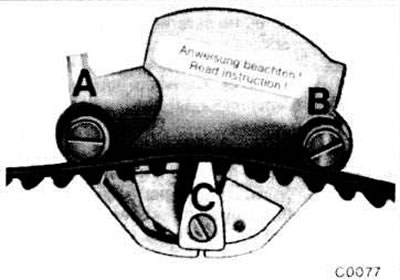

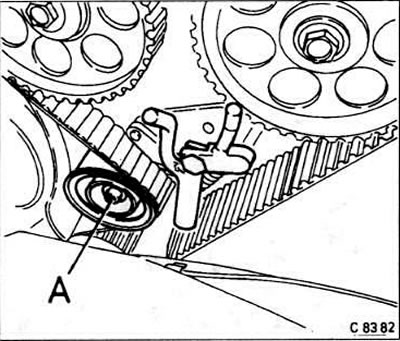

Pass the toothed belt between points A, B and C (see fig.C0077). In this case, the latch C must be in the cavity of the belt.

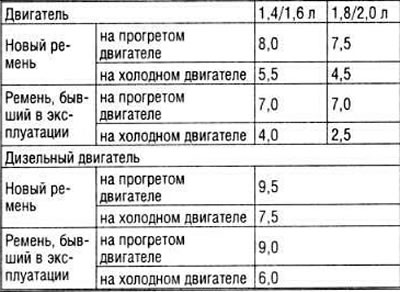

Values characterizing the degree of tension of the toothed belt

Adjustment

Loosen the coolant pump mounting bolts.

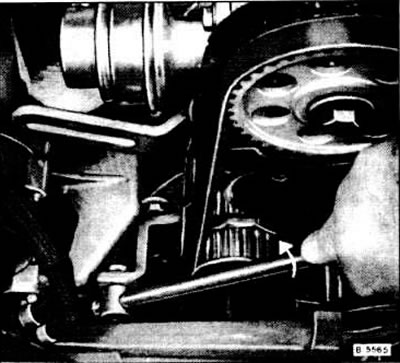

Turn the cooling system pump on the engine with a special Opel wrench or a regular 42.4 mm wrench (in the latter case, you must first remove the generator). When turning the pump up, the belt tension increases, down - decreases.

Install coolant pump mounting bolts, but do not tighten.

Remove the belt tensioner. Rotate the crankshaft one full turn in the direction of rotation, then check the tension again.

Attention! Adjusting the belt tension must be carried out until the device shows a stable value.

Tighten the cooling system pump mounting bolts to the following torque: for 1.4 and 1.6 l engines - 8 Nm; for engines with a volume of 1.8 and 2.0 liters - 25 Nm.

Install the front toothed belt cover.

Install generator. Put on the V-belt.

Attention! If there is no appropriate device for checking and adjusting the tension of the toothed belt, then this operation can be performed as follows. The belt is tensioned so that at point B (fig.A7872) it could be pushed through with a finger by 10 mm. Later, the belt tension must be checked with a special device. Until this is done, do not allow high engine speeds.

Toothed belt tension adjustment for 16-valve engines

For adjustment, you will need a special tool Opel KM-666. The engine must be cold.

Put on a new toothed belt.

Install the adjuster.

Make a mark with a waterproof felt-tip pen on the seventh tooth of the camshaft gear, counting in a counterclockwise direction (120°to crankshaft).

Turn the crankshaft clockwise until the mark on the camshaft pulley matches the mark on the cylinder head cover.

Attention! Rotate the crankshaft evenly, without jerking, to prevent jumping of the belt teeth.

Tighten the idler pulley mounting bolt in two steps:

- 1st stage: torque 25 Nm;

- 2nd stage: hold on to an angle of 45-60°.

Remove adjuster.

Turn the crankshaft to the TDC position of the 1st cylinder. The mark on the crankshaft pulley must align with the pin on the rear timing belt cover. At the same time, the marks on the camshaft pulleys must match the marks on the cylinder head cover.

Visitor comments