2. The friction disc moves freely on the grooves of the transmission input shaft. It is held in position between the flywheel and pressure plate and diaphragm spring pressure.

Friction linings are riveted to both sides of the disc.

3. The diaphragm spring is pinned and held in the clutch housing by support rings.

4. The release bearing is mounted on a guide bush at the front of the transmission. The bearing moves freely on the sleeve under the action of the release lever, which rotates inside the clutch housing.

5. The release lever is moved by the clutch pedal via a cable. As the friction disc wears out, the clutch pedal gradually rises from its original position.

Manufacturers do not provide any information regarding the need for clutch cable adjustment.

6. When the pedal is depressed, the release lever moves the release bearing forward, displacing the center of the diaphragm spring. The peripheral part of the diaphragm spring is displaced in the opposite direction and pushes the pressure plate away from the friction plate.

7. When the clutch pedal is not depressed, the diaphragm spring presses the pressure plate against the friction plate, which in turn rests against the flywheel. In this position, the drive from the crankshaft is transferred to the gearbox.

8. This arrangement of components allows you to replace the clutch assembly, release bearing and guide bushing oil seal without removing the engine or transmission from the vehicle.

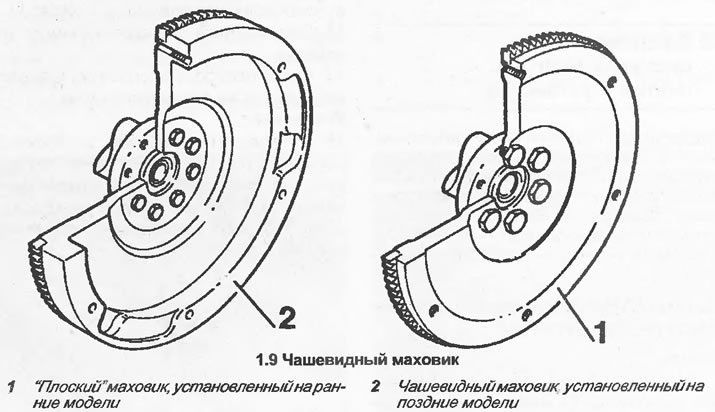

9. During 1992, the 1.8 and 2.0L models were gradually fitted with a cupped flywheel (see illustration).

This shape smooths rotation and reduces transmission vibration.

On these models, the transmission must be removed to replace the clutch.

Visitor comments