Note: When installing the driveshaft, use a new hub nut, washer and cotter pin, driveshaft retaining ring, and locking cotter pin of the lower arm nut to suspension strut ball joint. To work, you will need a ball joint puller. If the model is equipped with an intermediate shaft, see also Chapter 3.

Removing

1. Where applicable, remove the cap, then loosen the front wheel bolts.

Apply the handbrake, jack up and support the front of the vehicle on axle stands. Remove the wheel.

2. Remove the cotter pin from the castle nut of the hub (at the end of the drive shaft).

3. Loosen the hub nut. Hold the drive shaft stationary by temporarily installing two bolts in the wheel and inserting a metal rod between them. Remove the nut and washer from the drive shaft (see illustration).

4. Remove the locking cotter pin, then loosen the castle nut securing the lower arm ball joint to the suspension strut (see illustrations).

5. Using a special puller, release the ball joint connecting the lower arm to the suspension strut (see illustration).

6. To release the inner end of the drive or intermediate shaft from the differential (depending on the model), you need a lever. To release the right drive shaft, use a flat steel rod with a bevel at one end. The left drive shaft is more difficult to release, a rod with a rectangular section is required (see illustration).

7. Place a lever between the drive shaft and differential housing to release the drive shaft retaining ring from the differential. If necessary, use the rod as a drift to force out the left drive shaft. Place a suitable container under the differential to catch the oil that will flow out when the drive shaft is removed from the differential. Support the drive shaft without letting it hang under its own weight (see illustration).

8. Seal the holes in the differential to prevent further loss of oil and dirt from entering the block.

9. Remove the outer end of the drive shaft from the hub and remove the drive shaft from the vehicle (see illustration). If you cannot manually remove the drive shaft from the hub, lightly tap the end of the shaft with a mallet.

10. Do not allow the vehicle to rest on the wheels while at least one of the drive shafts is removed - this may damage the wheel bearings. If the vehicle needs to be moved, temporarily insert the outer end of the drive shaft (shafts) into the hub (hubs) and tighten the hub nut. In this case, the inner end of the drive shaft (shafts) must be supported, for example, it can be tied with twine to the bottom of the car. Do not let the drive shaft hang under its own weight.

11. Some models are equipped with a two-piece vibration damper mounted on the right drive shaft. If the vibration damper has been removed for any reason, it must be installed so that the distance between the inner end of the protective boot of the outer CV joint and the outer end of the vibration damper is as shown (see illustrations).

Installation

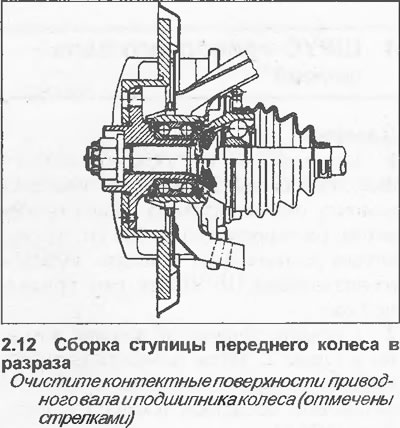

12. Before installing the drive shaft, make sure that the contact surfaces of the shaft and wheel bearing are clean (see illustration).

13. Begin installation by applying a small amount of molybdenum grease to the grooves of the drive shaft, then insert the outer end of the shaft into the hub. Install a new washer and hand-tighten the new hub nut.

14. Install a new retaining ring on the inner end of the drive shaft, then remove the plug you installed in the differential hole and push the drive shaft into the differential as far as it will go (see illustration).

15. Place a screwdriver or similar tool on the folded edge of the driveshaft inner CV joint (not on the metal cover and insert the shaft into the differential (or install it on an intermediate shaft) until the shaft lock ring snaps into place - pull the CV joint by the outer edge to make sure.

16. Reinstall the ball joint that secures the lower arm to the suspension strut, then install the castle nut and tighten it to the specified torque specifications. Secure the nut with a new locking cotter pin.

17. Gradually tighten the new hub nut with the torque specified in the Specifications. Hold the drive shaft stationary in the same way as when removing (see illustrations). If in this position none of the grooves in the nut aligns with the pin hole, tighten the nut an additional 9°and secure it with a cotter pin.

18. Install the wheel, then lower the vehicle to the ground and tighten the wheel bolts. Install the wheel cover where applicable.

19. Check and, if necessary, top up the gear oil level as described in Section 1.

Visitor comments