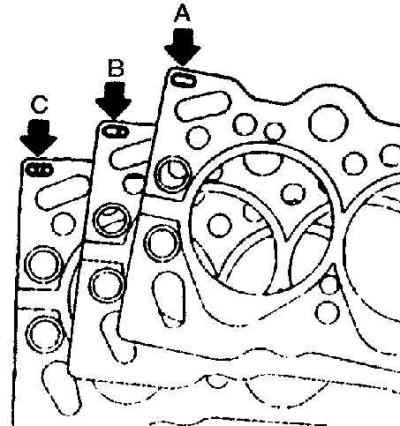

A - no hole - 1.4 mm

B - one hole - 1.45 mm

C - two holes - 1.5 mm

Removing

1. Drain the coolant from the cooling system.

2. Remove the intake and exhaust manifolds.

3. Remove the camshaft pulley.

4. Unscrew bolts of fastening of a back casing of a gear belt to a head of the block of cylinders.

5. Loosen the clamps and disconnect the coolant supply hoses to the thermostat housing and cylinder head.

6. Unscrew the nuts and remove the wires from the glow plugs.

7. Disconnect the connector from the coolant temperature sensor.

8. Disconnect the fuel supply lines from the fuel injectors and high pressure fuel pump and remove the lines.

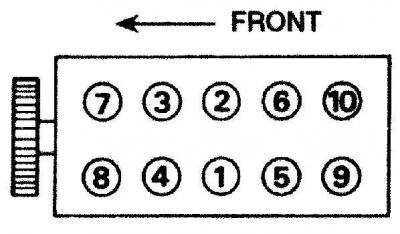

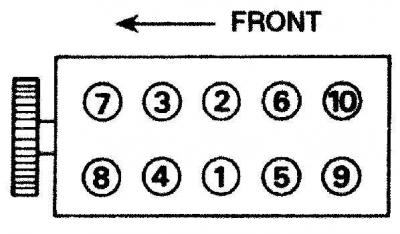

9. Gradually unscrew the cylinder head bolts in the reverse order shown in the figure.

10. Remove bolts with washers.

11. Remove the cylinder head and gasket.

Preparing for installation

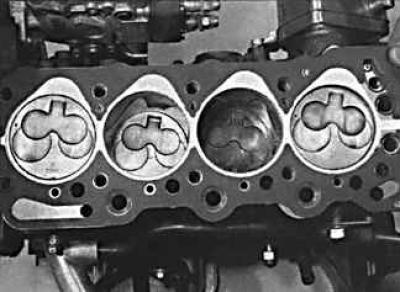

1. The mating surfaces of the engine head and cylinder block must be thoroughly cleaned of gasket residue and carbon deposits using a plastic or wooden scraper. It is also necessary to clean the tops of the pistons. When cleaning, exclude the possibility of cleaning products getting into the oil channels of the cooling system. Thoroughly clean the inner surfaces of the cylinders.

2. Check the mating surfaces of the engine head and cylinder block for defects. Minor damage is eliminated by machining. Also using a metal ruler and feeler gauge, check the flatness of the surfaces.

3. Clean the bolt holes in the block. Screwing a bolt into an oil-filled hole can rupture the block due to hydraulic pressure.

4. Depending on the amount of protrusion of the pistons from the cylinder block, it is necessary to use a head gasket of a strictly defined thickness. Gasket thickness identified by holes punched in the left front corner of the gasket (see fig. The location of the holes for identifying the thickness of the cylinder head gasket).

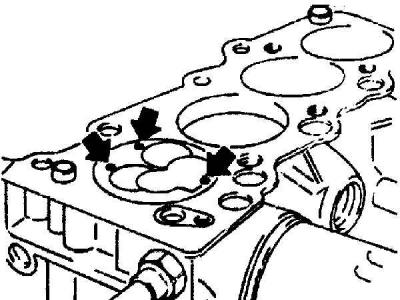

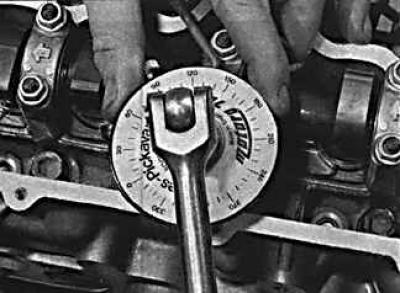

5. Check that the crankshaft is at top dead center on the #1 piston. Install the dial gauge on the bracket to the cylinder block. Install a measuring tip on the cylinder block and set the indicator scale to 0. Place a measuring tip on the piston of the first cylinder and turn the crankshaft slightly in both directions and note the highest value on the indicator. Write down this value. Check piston protrusion at three points (points are indicated by arrows).

6. Measure the piston protrusion on cylinder N4 in the same way. Then turn the camshaft 180°and repeat the piston protrusion measurement on cylinders 2 and 3. Rotate the camshaft 540°and return it to its original position.

7. Determine the average piston protrusion by adding the 12 piston protrusions and dividing the total by 12. Using the average piston protrusion, select the cylinder head gasket (see table).

|

Piston protrusion

|

Gasket thickness

|

|

0.58 - 0.64 mm

|

1.40 mm

|

|

0.65 - 0.70 mm

|

1.45mm

|

|

0.71 - 0.78 mm

|

1.50 mm

|

Installation

Warning! When installing the cylinder head, new bolts must be used.

1. Wipe mating surfaces of cylinder block and cylinder head.

2. Check that the two guide pins are installed in the cylinder head and install the cylinder head gasket.

3. Check that the crankshaft pulley mark is aligned with the pointer, and the camshaft is installed in the cylinder head with the cams of the first cylinder pointing up.

4. Install the cylinder head.

5. Lubricate the cylinder head bolts with engine oil and, being careful, insert them into their sockets. Tighten the head bolts by hand.

6. In the sequence shown in the figure, tighten the cylinder head bolts in several stages.

7. Further installation is carried out in the reverse order of removal. Pour coolant into the cooling system.

Visitor comments