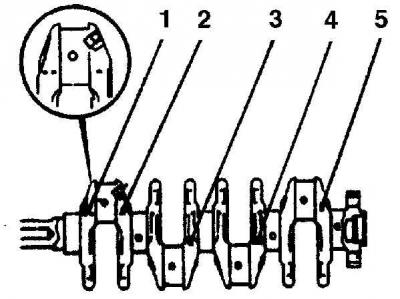

Place for marking the diameter of the bore of the bearings of the diesel engine 1.7 l

Diesel engine 1.7L

To select the working clearance of bearings, 4 different inserts are used, which are indicated by a colored mark on the end. The color of the label indicates the thickness of the liner and increases in sequence depending on the color: green, brown, black or blue.

If a bearing shell needs to be replaced, first check and record the identification mark located on the crankshaft adjacent to each bearing journal.

Record the main bearing bore size identification markings that are located on the bottom mating surface of the rear of the engine block.

According to the bearing bore code and crankshaft journal code, select a new main bearing shell using the following table. Crankshaft codes are on the left side, bearing bore codes are on the top. The bearing type is selected at the intersection of the two lines.

|

1

|

2

|

3

| |

|

line

|

black

|

brown

|

green

|

|

lines

|

blue

|

black

|

brown

|

Other engines

It is possible to use both standard and reduced size crankshaft main bearings. The required bearing size can be determined by measuring the crankshaft journal.

Checking the operating clearance of the bearing

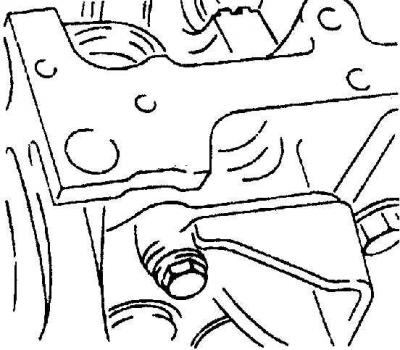

1. Clean the back of the bushing and its mounting location in the cylinder block and main bearing caps.

2. Install the earbuds into place, making sure that the tab on the earbud aligns with the groove on the cover.

3. One method, which involves having a micrometer to measure the diameter of the bores, is to install the main bearing caps along with the bushing on the cylinder block and screw them to the required torque. Measure the inside diameter of each assembled pair of bearing shells. Measure the diameter of each crankshaft main journal. Subtract the corresponding diameter of the crankshaft main journal from the measured bearing diameter.

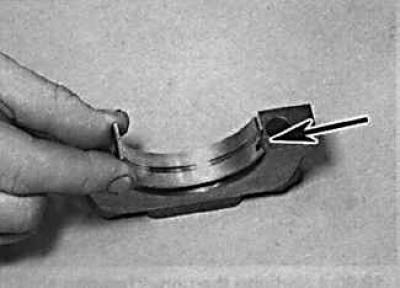

4. Second (and more accurate) the method is to use a product known as Plastigage. This is a round plastic rod that is compressed between the bushing and the crankshaft journal. After removing the main bearing cap, the deformed plastic rod is measured with a special gauge, which is included in the Plastigage kit. The procedure for using Plastigage is as follows.

5. On the liners installed in the cylinder block, install the crankshaft without lubrication. The crankshaft journals and liners must be perfectly clean and dry.

6. Cut off a few pieces of the plastic Plastigage rod (they should be slightly shorter than the width of the main bearings) and install on each crankshaft journal.

7. Install the covers with the bottom liners and tighten the mounting bolts to the required torque. Do not rotate the crankshaft while measuring clearance with the Plastigage method.

8. Unscrew the cover of the insert attachment, remove it and attach a scale ruler to the deformed plastic rod. By comparing the width of the deformed plastic rod with the reference width on the scale bar, determine the amount of gap.

9. Finally, carefully clean the traces of Plastigage - the material from the liners and the crankshaft.

Visitor comments