Removing the front suspension strut assembly

In the front wheel suspension units, some parts can be dismantled and mounted on their own. Although for certain types of work, tools from the workshop are needed. Damaged wheel suspension parts cannot be straightened or welded and must always be replaced.

Remove the front wheel.

Using pliers, remove the brake hose fixing clip at the bottom of the suspension strut and remove the brake hose from the bracket.

Remove the stabilizer pendulum from the suspension strut. At the same time, with an open-end wrench, press the ball joint pin in the opposite direction.

Loosen the screw connection of the spring strut and remove the bolts from the steering knuckle.

Fold out the steering knuckle and support the suspension strut so that it does not fall after loosening the upper mount.

Unscrew the fixing nut on the suspension strut dome in the engine compartment. At the same time, press the piston rod in the opposite direction.

Pull the shock absorber down.

If the suspension strut is only dismantled and not repaired, before installation, check the tightening torque of 55 Nm for fastening the thrust bearing to the shock absorber piston rod.

When mounting, insert the spring strut into the dome from below.

Tighten the suspension strut at the top (55 Nm).

Screw the suspension strut down. To do this, insert the old bolts from front to back (in the direction of travel) and tighten to 100 Nm.

Tighten the stabilizer arm to the shock strut with a new self-locking nut to 65 Nm.

Attach the brake hose.

After installation, immediately check the wheel alignment. At the same time, replace the old bolts and nuts for setting the camber with new ones. Tightening torque: 50 Nm, then 90 Nm + 45°to 60°.

Removing the front shock absorber

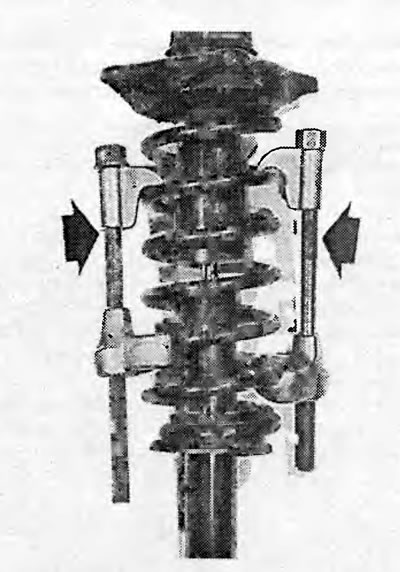

For this work, a spring clamping device is absolutely required. You need to have at least two spring clamping devices, and preferably three. Without the use of a spring clamping device, it is impossible to loosen the fixing nut at the top of the shock absorber piston rod, because. the spring is under high preload. Parts of the suspension strut can fly apart as in an explosion - risk of injury! In addition, an unloaded spring can no longer be installed. The spring tensioner is available from parts stores.

Spring clamps (arrows) are used to disconnect the spring from the shock absorber when the suspension strut is dismantled.

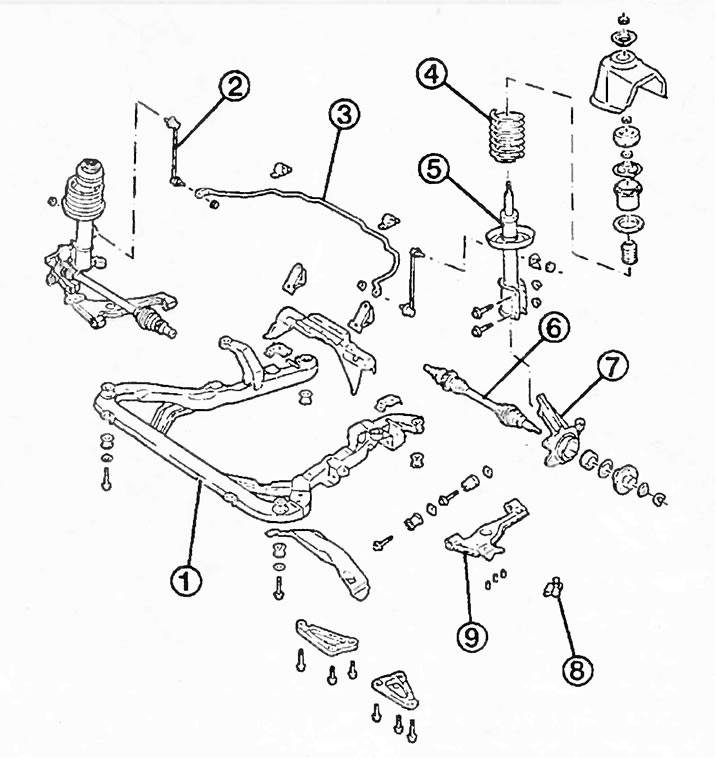

The image of the front wheel suspension exploded, as if in an explosion, shows us:

1 - front axle support;

2 - stabilizer connecting rod;

3 - stabilizer;

4 - spiral spring;

5 - shock absorber;

6 - left drive shaft;

7 - rotary fist;

8 - axle hinge;

9 - transverse lever.

Dismantle shock absorber (see previous section).

Clamp the shock absorber in a vise at the very bottom where the steering knuckle is attached.

Install the clamping device on the coils of the spring and compress the spring.

To prevent the clamp from slipping, cover the corresponding coils of the spring with adhesive tape.

Loosen the nut at the top of the suspension strut with a curved socket wrench. Press the shock absorber piston rod in the opposite direction.

Remove the upper shock-absorbing ring with thrust bearing from the piston rod.

Remove the upper spring seat and buffer.

Remove the spring along with the spring tensioners.

When installing, tighten the new self-locking nut to secure the thrust bearing to 50 Nm.

Loosen the spring and mount the suspension strut.

After installation, immediately check the wheel alignment (In workshop). To install the wheel alignment, replace the old fixing bolts and nuts with new ones.

Tip: shock absorbers should always be stored upright. When stored horizontally, shock oil flows into the upper area, and the shock absorber may knock during operation. In order for the oil to glass back, you need to put the shock absorber in an upright position for 24 hours at room temperature, with the piston rod fully extended.

Removing the front stabilizer

If it is necessary to dismantle the Vectra stabilizer, to do this, first loosen the fastening of the front axle support as a whole so that the stabilizer mounting bolts become accessible. This job requires special tools and professional knowledge - typical workshop work!

Removing the wishbone of the independent suspension

Raise the car and remove the front wheel.

Dismantle the shock absorber.

Unscrew the fixing nut of the axle joint and remove the bolt from the steering knuckle.

Press the axle pivot out of the steering knuckle.

Loosen the transverse arm mounting bolts.

Remove the transverse link from the mount in the body of the front axle. To do this, slightly press down the transverse lever.

When mounting, use new bolts and nuts.

The tightening of the screw connections is carried out on a loaded vehicle, while each front seat must have a load of 70 kg.

Tightening torques: wishbone on front axle support 90 Nm 4-75°to 90°, axle pivot on steering knuckle 100 Nm. The fixing bolt of the axle joint, when viewed in the direction of travel, insert from behind.

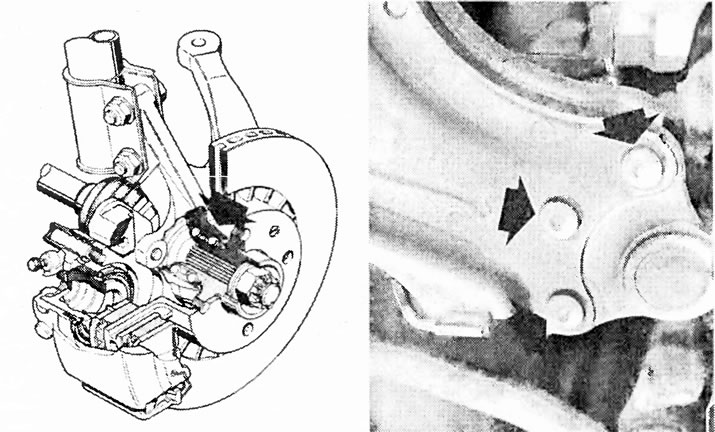

Left:The front wheels of the Vectra are fitted with double row ball bearings. Adjustment of these bearings is not possible and is not required. If there is play in the wheel bearings, they must be replaced.

On right: the axle pivot is firmly riveted to the wishbone. If you need to change the hinge, then you should drill out the heads of the rivets (arrows). When mounting a new axle joint, use only special bolts and nuts from Opel.

Dismantling the axle joint

Remove the independent suspension control arm.

The axle joint has a riveted connection to the wishbone. Drill 12mm centered rivet heads

Knock out the remaining rivets with a punch.

Treat the holes with an anti-corrosion agent.

When installing a new axle joint, use special bolts and nuts from Opel. Insert the bolts from the upper side of the transverse arm and tighten the nuts from the lower side of the control arm. Tightening torque: 35 Nm.

Mount the transverse arm.

Dismantling the steering knuckle

Remove the front wheel.

Press the dust cap off the wheel hub.

Remount the wheel.

With the vehicle on the ground, unscrew the hex nut on the drive shaft. Pay attention to the large tightening torque!

Raise the vehicle and secure.

Remove the front wheel.

Unscrew the brake caliper from the steering knuckle and hang it on a tie wire - the brake hose remains connected.

Unscrew the fixing bolt of the brake disc and remove the brake disc from the wheel hub.

Unscrew the brake shield and the ABS speed sensor from the steering knuckle.

Unscrew the fixing nut of the steering knuckle and remove the bolt from it. Remove the axle pivot from the steering knuckle.

Unscrew the tie rod joint nut and press the joint away from the steering knuckle.

Unscrew the screw connection: suspension strut support tube/steering knuckle.

Remove the steering knuckle from the drive shaft. If necessary, use a commercially available wheel hub puller to press the steering knuckle off the drive shaft.

Suspend the drive shaft on the wire and do not allow it to sag.

When mounting, use new bolts and nuts.

Screw the steering knuckle to the suspension strut support tube, see the top of this article for more information «Removing the front suspension strut assembly».

Slide the steering knuckle onto the drive shaft.

Screw the steering knuckle to the axle joint, see section «Removing the transverse arm».

Everything you need to pay attention to when tightening a hex nut is given in chapter «Gearbox and final drive» In chapter «Removing the drive shaft».

Left:knock out the dust cap (1), as shown here with a flat chisel (2) from the wheel hub.

On right: then unscrew the hex nut (3) wheel bearing mountings. Attention, the nut is tightened with a large torque.

Removing the front wheel bearing

The wheel bearing is pressed into the housing with its outer ring, the wheel hub is pressed into the inner ring of the bearing The new wheel bearing must never be driven into the seat with a hammer, otherwise at the same time «mounted» next damage. Therefore, it is better to change only the steering knuckle yourself.

You must entrust the direct pressing out and pressing in of the bearing to a workshop where special punches and a repair press are available.

Visitor comments