Voltage measurement

When checking and repairing electrical and electronic equipment of a car, it is necessary to measure various electrical quantities. In order to be able to correctly read the measuring value, you must first of all have an accurate measuring device. How to connect the measuring device correctly and what you need to pay attention to for individual measurements, you will find in the following sections.

Test lamp: This is practically a test lamp with a needle contact, the needle of which can simply pierce the insulation of the wire under test. The clip on the lamp wire is attached somewhere on the bare metal of the machine, on the so-called ground. The lamp, first of all, gives information that there is voltage in general. By the brightness of its glow, you can approximately estimate the magnitude of the voltage.

Diode tester: Electronic components cannot be measured with a traditional test lamp. It consumes a lot of power and can damage electronic components. Anyone who wants to make measurements in this area needs a diode tester with light diodes.

Voltmeter: Measurements are made more accurately using a multi-range voltage meter with a pointer or digital display. Due to the very low current consumption, there is no danger of damage to electronic components in this device.

To measure battery voltage (as an example) wire marked with «-», connects to the battery negative. Wire marked with a sign «+» connected to the positive pole.

If the device shows, for example, only 10.4 V, then there is a short circuit in one of the battery cells. It is also interesting to measure the voltage while the starter is running. If the device shows only 6 V, then things are probably not going well with the battery.

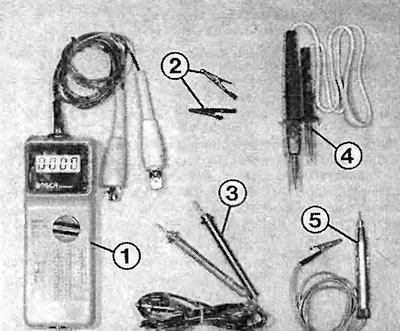

Measuring instruments for electrical and electronic equipment of the car:

1 - precision engine tester with a digital indicator, to it «crocodiles» (2) and measuring tips (3);

4 - LED voltage indicator (also suitable for electronic components);

5 - a traditional voltage indicator with an incandescent lamp.

Voltage measurement «to ground»: connect wire «+» voltmeter to the clamp on which there is voltage, wire «-» to a bare body or engine part. These parts are connected by thick wires to the minus of the battery, due to which it is possible to obtain accurate measurement results.

Often voltage is measured between two specific pins (e.g. control unit). A description of how to connect the meter and what the voltage should be is then part of the test instructions.

You can also check with a voltmeter whether the cable connected to ground is in order: connect the wire «+» meter to battery positive, meter wire «-» connect to the end of the ground wire. If the ground connection is OK, the meter should show full battery voltage.

Current measurement

Whether current is supplied to the consumer is measured with an ammeter or in the appropriate multitester mode.

To do this, open the electrical circuit and connect the device between the freed poles.

In practice, it looks like this: disconnect the wire connector to the consumer and connect the device between the connector and the contact tongue.

The current is measured, for example, if there is a suspicion that somewhere in the car's network there is a hidden current consumer that discharges the battery during the night. To determine the location of the current leakage, disconnect the battery ground wire and connect an ammeter between the pole and the battery wire. If the device shows a current, then the electrical circuit will be determined: remove the fuse one by one and instead connect an ammeter to the contact tabs in the fuse box. This way you will know which electrical circuit has a leak. Then, using the fuse table in the next chapter, compare which consumers are connected to this electrical circuit and check them one by one.

Tip: when measuring, the ammeter contacts must also be connected to the corresponding pole. Otherwise, the arrow will deflect in the wrong direction. The meter or its fuse will be destroyed if the measured current is significantly higher than the selected measuring range. Do not connect a measuring device between the battery terminal and the main wire and do not operate the starter. Resulting currents (up to 150 A) too large for any standard measuring instrument. If measurements are to be taken at this location, a measuring resistor is required (shunt), which is connected to the wire during measurement.

Resistance measurement

An accurate measurement of the resistance at a particular node only makes sense when there is an accurate measuring instrument. Otherwise, there will be doubts about the reliability of the measurement results.

Using an ohmmeter, you can, for example, find out what internal resistance is in a particular circuit element. You will find the data in this book where it is needed.

Meter wires (while the poles are indifferent) connected to two terminals of the node.

Or measure the resistance «to ground»: one wire is connected to the circuit element, the second - to the engine block or to the body.

Further, by measuring the resistance, it can be established whether there is conductivity in the wire or in the switch (the measurement result should be 0 ohm), or the circuit is interrupted somewhere (then the measured value is «infinity» = ∞ Ohm).

Visitor comments