Charging voltage test

Connect a voltmeter between the thick red alternator wire and ground

Start the engine at medium speed.

With a working voltage regulator, the device will show approximately 14.0 to 15.0 V.

If this is not the case, then check the graphite brushes or replace the regulator.

Otherwise, the generator itself is faulty.

Checking graphite brushes

Bosch generator

On the alternator cover, unscrew the three Phillips head screws, unscrew the B+ wire and remove the cover clips from the back of the clips, remove the cover.

Remove the regulator from the generator. To do this, loosen the two slotted screws.

Slightly tilt the adjuster so that the graphite brushes do not hang down.

Measure the protrusion of the graphite brushes.

The new graphite brushes are about 13mm long; allowable wear 5 mm.

Replacement of graphite brushes

Bosch generator

For this job you need a soldering iron, electrical solder, and knowledge of soldering.

Remove the regulator from the generator as described above.

Unsolder the connecting ends of the wire, remove the brushes.

Remove the pressure spring from the old brushes and install on the new brushes.

Solder the connecting ends of the wire.

Don't use a lot of tin solder and work quickly so that the connecting ends of the wire don't get soaked in tin. Otherwise, they will become rigid.

Checking graphite brushes

Delco Remy generator

Dismantle the generator.

Unscrew the three screws on the bearing cover.

Remove the rotor with drive bearing and belt pulley from the stator.

Unscrew the ends of the stator winding from the diode support, remove the stator from the slip ring bearing.

Remove excitation diodes (three nuts, one screw).

Unscrew both screws of the graphite brush holder, remove the insulating washer.

Disconnect the connecting tabs of the graphite brushes from the bracket, remove the brushes from the guide and measure their length.

If the total length is less than 20 mm, they must be replaced.

Replacement of graphite brushes

Delco Remy generator

The springs of graphite brushes are fixed in the bracket with a wire bent in the form of a hook.

After installing new brushes, do not forget their wire hooks.

When assembling the generator, the long end of the wire is inserted into the hole in the slip ring bearing.

Regulator replacement

Delco Remy generator

Dismantle and disassemble the generator as described below in the section «Checking graphite brushes».

Disconnect connectors.

Unscrew the fixing screw of the regulator and remove the regulator.

Tip: with the graphite brushes dismantled, you can simultaneously check the copper slip rings of the generator armature (graphite brushes move on them). If they have deep wear marks, they can be bored out in an automotive electrical equipment repair shop.

Dismantling the generator

Disconnect the battery ground wire.

Remove the air filter housing together with the air intake hose and, where present, with the air intake hood, see the air filter chapter.

Before removing the V-ribbed belt, mark the direction of its rotation.

Counteracting the force of the spring, turn the poly-V-belt tensioner with an overhead wrench (clockwise) until the holes of the tension roller flange and the tension roller itself match.

In this position, fix the tension roller with a suitable pin or Phillips screwdriver and carefully remove the overlay wrench.

Remove poly V-belt.

With an 8 valve engine, disconnect or remove the Multec central injection multi-pin connector. Remove the cable duct from the camshaft housing and set aside.

With a 1.6L 16V engine, remove the air duct from the bottom of the intake manifold and from the throttle body and fold down.

For everyone: remove the stop [stop] against rotation.

Unscrew the accessible fixing bolts of the generator.

Remove the alternator bracket mounting bolts.

Remove the generator cables.

Take out an arm together with the generator upwards from an impellent compartment.

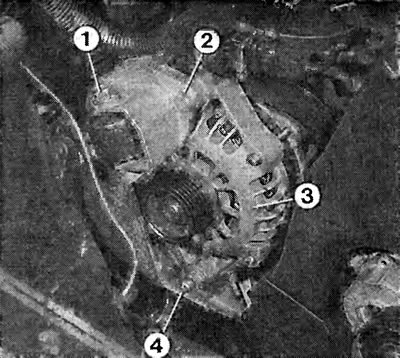

The generator in the model with an 8-valve engine 1.6 liters. The numbers indicate:

1 - stop [stopper] against turning;

2 - top fixing bolt;

3 - generator;

4 - bottom fixing nut.

Unscrew the mounting bolts of the generator on the bracket.

The following torques apply when screwing on: alternator on mounting bracket 35 Nm, mounting bracket on engine block 35 Nm, support and trim on intake manifold and alternator 18 Nm, anti-rotation stop 60 Nm.

Fit poly V-belt, paying attention to the direction of rotation.

Install the wrench on the tension roller. Remove the rod and carefully loosen the tension roller.

Check the correct alignment of the belt on the belt pulleys.

Visitor comments