Valve body

In general, knocking in the cylinder head area indicates one or more defective hydraulic tappets. In this case, the corresponding tappet is not repaired, but replaced.

But noise in the valves can also occur with serviceable hydraulic pushers if:

- shortly before starting, the lubrication of the pushers is not yet provided;

- before that, the car was working at full load at a high external temperature;

- haven't driven the car for a long time. In this case, the noise in the valves disappears when the engine warms up;

- When the oil level is extremely low, the oil pump sometimes sucks in air.

Tip: The knock of hydraulic pushers can also be associated with a defect in the cylinder head gasket - in this case, combustion gases enter the lubrication channel.

Hydraulic pushers

Replacement of hydraulic pushers

In an 8-valve engine, it is possible to dismantle a separate hydraulic pusher without dismantling the camshaft. This requires a valve clamp (see also section «Camshaft removal»), with which the corresponding valve can be pressed down and this hydraulic pusher can be removed.

- Dismantle the camshaft (s) as described above.

- On an 8 valve engine, remove the appropriate swing arm. Pay attention to the stops.

- Remove the old hydraulic lifter from the cylinder head. At 16V this is best done with a small suction cup.

- If the hydraulic pusher is mounted again, then it must be installed in the same place.

- Fold hydraulic pushers in reverse mounting position (bowl bottom down) so that oil does not leak out in the pusher.

- When installing a new pusher into the guide, lightly grease the work surface.

- Insert the tappet and mount the camshaft again (s).

- When applying a toothed belt, be sure to pay attention to the valve timing.

- Check toothed belt tension.

Tip: The engine must not be started for the next 30 minutes. Unloaded hydraulic pushers are pressed by their pressure springs to the position of maximum stretching. As a result, the valves at the first revolution of the camshafts open so much that they collide with the pistons. Only after half an hour of waiting, the pressure in the hydraulic pushers will be released. Then, to be sure, crank the engine twice by hand to make sure that no piston can hit the valve.

Dismantling

8 valve engine

The cylinder head can only be removed when the engine is cold, as a hot cylinder head may be deformed after dismantling. When installing the cylinder head, you will need a new gasket and new bolts.

- Disconnect the ground wire on the battery.

- Tag and disconnect all electrical wires on the cylinder head, intake manifold and injection system.

- Do the same with the hose wires.

- Drain the coolant into a container.

- Disconnect and remove the upper coolant hose from the thermostat housing. Also remove the upper coolant hose from the outlet pipe.

- Disconnect the wire connector on the thermostat housing.

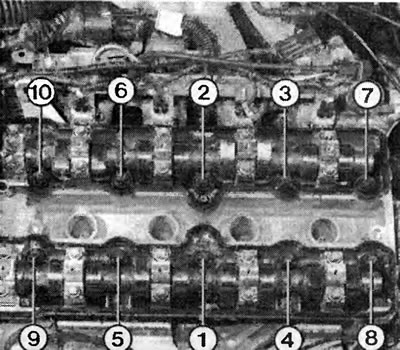

On a 16V engine, the bearing caps must be unscrewed to remove the camshafts. Bearing caps are numbered from «1» before «10». When mounting, you must install them again in the same place.

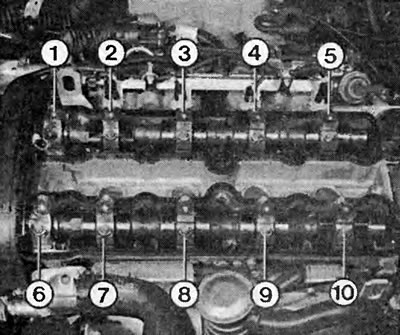

The photo shows the components of an 8-valve engine. The numbers indicate:

1 - intake manifold;

2 - intake manifold gasket;

3 - cylinder head;

4 - top mounting of the generator;

5 - cylinder head gasket;

6 - exhaust manifold gasket;

7 - exhaust manifold;

8 - branch pipe for preheating the intake air.

- Remove the support and trim on the generator.

- Remove the front toothed belt cover.

- Set the crankshaft to 90°before ignition of the 1st cylinder.

- Loosen and remove toothed belt.

- Unscrew fixing bolts of a cover of a head of the block of cylinders and remove a cover.

- Remove the camshaft pulley, see section «Camshaft removal».

- Unscrew the top fixing bolts of the bottom cover of a gear belt.

- Unscrew the front exhaust pipe from the exhaust manifold.

- Unhook the throttle cable and disconnect from the counterhold.

- Mark and dismantle the supply and return fuel lines.

- Loosen the cylinder head bolts in reverse order as shown below. First ¼ turn, next ½ turn, then unscrew them completely.

- First, remove the camshaft housing.

- Remove the pendulum levers, stops and hydraulic pushers from the cylinder head. Consider their location.

- Remove the cylinder head with intake manifold and DIS ignition module. If it does not come off immediately, help with light blows with a plastic hammer.

Dismantling

16V

The dismantling of the cylinder head in a 16V engine, of course, must be carried out in the same way as in an 8-valve engine. A torx wrench is required to unscrew the cylinder head bolts. Consider:

- The engine must be at 60°before TDC ignition

- In a 16V engine with a displacement of 1.6 liters, additionally remove the rear toothed belt cover.

- On a 1.8L and 2.0L 16V engine, remove both camshafts to gain access to the cylinder head bolts.

Checking the dismantled cylinder head

- Remove the old head gasket.

- The sealing surfaces of the cylinder head and engine block must be clean and free of gasket residue.

- If necessary, use a chemical gasket remover.

- Do not scrape the soft sealing surface of the cylinder head with hard tools. Notches can cause subsequent damage to the head.

- Check the cylinder head for deformation, especially if its gasket is damaged due to overheating.

- Lay a long metal ruler or a guaranteed straight metal angle along the cleaned sealing surface of the cylinder head.

- Check with a template whether the deflection in any place exceeds 0.05 mm. In this case, the cylinder head must be flat ground before assembly.

- The cylinder head can only be bored within certain limits. Its minimum height on an 8 valve engine, from top to bottom sealing surface, must be kept within a tolerance of 96.00±0.1 mm.

- In a 16V motor, the minimum height is 135.63 mm±0.05 mm.

- After overheating, cracks may also appear in the cylinder head. You should check this when repairing a dismantled head.

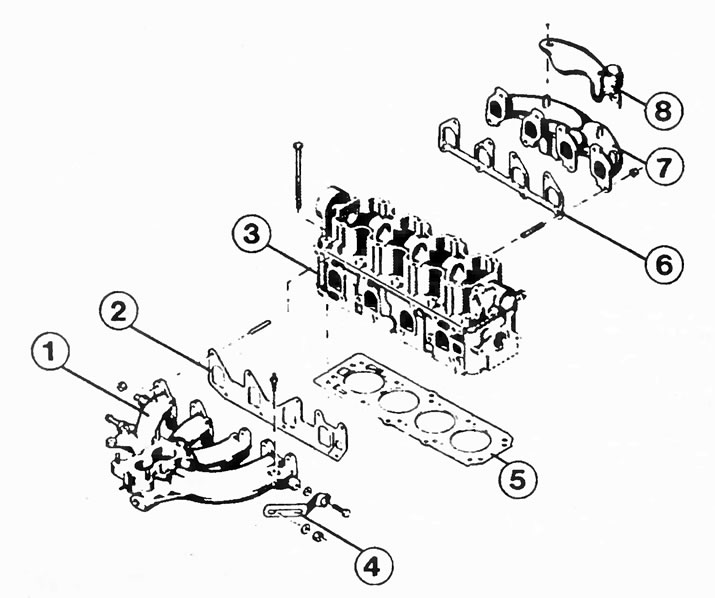

The photo shows the cylinder head bolts for an 8-valve engine. To ensure that the cylinder head cannot be deformed during installation, the tightening sequence of the head bolts must be followed very precisely. In this case, the final tightening torque is reached in several stages, see text below.

Installation

Installation of the cylinder head, of course, is carried out in the reverse order of dismantling. But some points should be paid special attention.

- The threads in the engine block bolt holes must be clean and undamaged, otherwise the torque will be distorted when the bolts are tightened.

- The bolt holes in the engine block must be free of oil or water, otherwise the cast material may break in the area of the threaded holes.

- Rotate the crankshaft so that neither piston is at TDC, otherwise the open valve may collide with the piston when installing the cylinder head.

- Place the cylinder head gasket on the engine block so that the designation «Top» («OBEN/TOR») facing up and toward the timing belt side of the engine.

- Install the cylinder head with the sealing surfaces cleaned. Do not use any sealant.

- Lightly oil all bearing journals.

- On an 8-valve engine, evenly lubricate the sealing surface of the cylinder head to the camshaft housing with Opel No. 1503166 sealant and install the camshaft housing.

- Screw in the new cylinder head bolts until they touch the head surface.

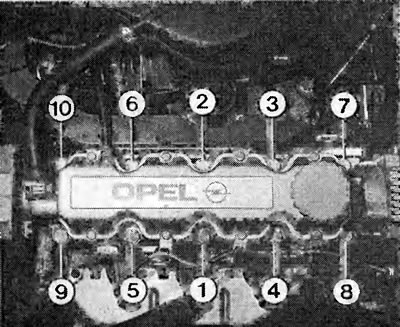

- Tighten the cylinder head bolts in the sequence shown below.

- 1st pass 25 Nm.

- In the 2nd step, tighten the bolts in the same sequence by 60° (8-valve engine 1.6 l) or 90° (other engines), for this use a hard key with graduated division. As an aid, you can use a welding wire that is placed on the wrench at an angle of 60°and 90°.

- With the 3rd pass, the bolts are tightened again by 60°or 90°respectively.

- In the 4th pass, tighten the bolts for the last time by 60°or 90°respectively.

- After that, all bolts are finally tightened, and they must not be tightened again under any circumstances.

- During further installation, pay attention to the adjustment of the throttle cable, the correct level of coolant and oil, as well as the correctness of all connections to the ground.

The photo shows the sequence in which the cylinder head bolts are tightened for a 16V engine with a displacement of 1.6 liters. The final tightening torque is reached in several steps, see text above. The cylinder head bolts on the 1.8/2.0L engines are tightened in the same sequence as shown here.

Visitor comments