If the filter paper is dirty because the filter has not been replaced in a timely manner, the safety valve will operate. It opens, and the oil bypasses the filter, the oil supply is guaranteed. However, unfiltered engine oil contributes to increased wear of the bearings. From the filter, the lubricant enters through the holes in the cylinder block to the lubrication points of the crankshaft, in addition to the cylinder head and valve mechanism.

Through other holes, the oil flows back into the crankcase, from where it can be taken by the oil pump for new circulation.

Oil pump

Behind the poly V-belt pulley is perhaps the most important auxiliary engine unit - the oil pump. Driven directly by the crankshaft, an eccentrically positioned outer toothed gear rotates in a slightly larger internal toothed gear. This creates a constantly rotating sickle-shaped cavity, which gives this pump the name sickle pump. Such a pump, even at low speeds, has a good supply power. At full throttle or maximum speed, the pump delivers about 30 liters per minute. This lubrication flow provides not only lubrication, but also, to a large extent, cooling of the engine.

Oil temperature

For good «well-being» engine oil temperature is critical. Although production Vectra models do not have an oil temperature thermometer, which can determine how the engine's thermal balance is.

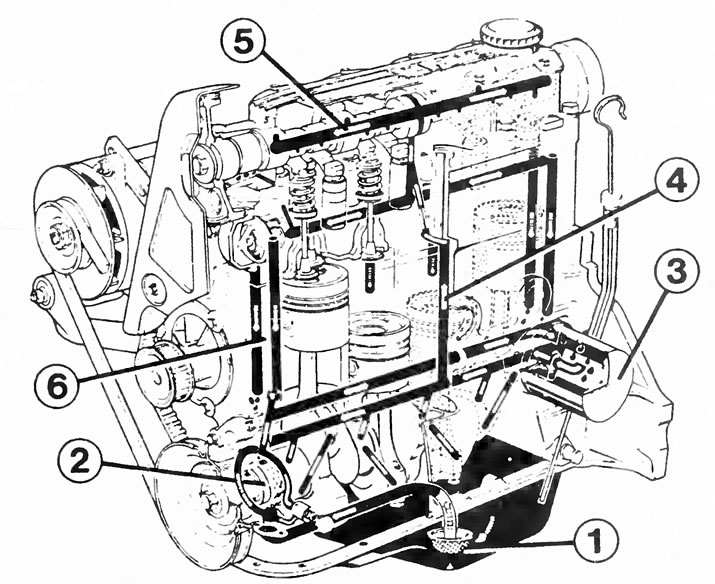

Oil circulation in an 8-valve engine. It passes through the following nodes:

1 - crankcase with oil cleaning mesh;

2 - oil pump (on the crankshaft);

3 - replaceable oil filter;

4 - vertical pipeline;

5 - camshaft;

6 - pipelines for flowing oil.

The temperature is usually measured at the oil filter flange or in the crankcase; where the oil temperature is lowest. However, temperatures of up to 300°C can occur on the piston rings. If you have already installed an oil temperature thermometer after purchasing your car, then: according to Opel, the temperature measured in the crankcase at a level of 1 cm from the bottom can reach 150°C under extreme conditions, although the condition for this is the use of high-quality engine oil, which it still has a sufficient lubricating effect.

But too low oil temperature is also harmful to the engine. At temperatures below 60°C, the additives in the oil partially lose their effectiveness, which leads to a significant increase in wear. Therefore, after starting a cold engine, if possible, do not raise the speed higher than 3500 rpm until the oil has warmed up to about 60°C. The starting point in our models without an oil thermometer is that in order to achieve The operating temperature of the oil requires twice the amount of time required for the coolant.

Oil pressure

The oil pressure at its temperature of 80°C should reach the following indicators:

- At 2000 rpm engine - minimum 2.0 bar.

- At idle - at least 0.3 bar.

Exact information about the oil pressure can only be given by the appropriate measuring device supplied as an option. In the standard version, there is only an approximate possibility of monitoring by means of an oil pressure switch, which, during operation, switches on a warning light on the instrument panel in case of insufficient pressure. This pressure switch is located on the Vectra on the right rear of the oil pump housing.

But the oil pressure should not be too high. The pressure control valve expands the suction side if the pressure rises too high due to cold or very viscous oil. Oil pressure monitoring is discussed in more detail in the Instruments chapter.

However: if you want to accurately measure the oil pressure in your engine, then you need to unscrew the oil pressure switch and connect a pressure gauge with an accurate indication instead.

As already mentioned, the control valve does not allow too much pressure increase when the oil is cold. If the control lamp lights up or flashes when the engine is warm, this indicates insufficient oil pressure. In this case, the pressure control valve must be checked.

- Remove the hex head bolt from the rear side of the crankshaft pulley.

- Remove the pressure spring from the hole and the control piston from the hole. Pay attention to the installation position!

- Clear the details. The surface of the control piston must be free of nicks or crusts of dirt particles. There should be no wear on the pressure spring.

- Replace damaged parts.

- Use a new copper O-ring when installing.

- Tighten the bolt to 30 Nm.

Visitor comments