You will need a valve lapping tool and lapping paste to get the job done.

Execution sequence

1. Remove the valve stem seal (see «Oil seals - replacement»).

2. Remove the valve from the guide sleeve.

3. Check the condition of the valve guides. The guides should sit tightly in the body of the head, with no traces of their displacement during timing operation.

4. Apply lapping paste to the working edge of the valve.

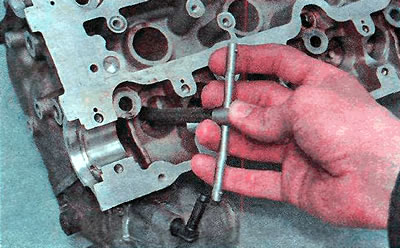

5. We install the valve in the head of the block and fix the device for lapping the valves on its stem.

6. Pressing the valve to the seat, turn it from side to side. After 10-15 strokes turn the valve 90°and continue lapping.

Recommendation. Much more convenient and efficient lapping of valves can be done using a pneumatic device mounted directly on the valve disc, which allows for better pressure of the valve disc to the seat.

However, in this case, in addition to the device itself, you will need a compressor that provides a constant pressure of at least 2-3 kgf / cm2.

7. We perform grinding until a uniform annular rim is formed on the valve disc...

...and on his saddle.

8. Carefully remove the remnants of lapping paste from the valve and its seat.

9. Similarly, we grind the remaining valves.

10. We assemble in the reverse order.

Recommendation. After lapping, check the tightness of the valves (see above, «Cylinder head - checking the technical condition») and repeat if necessary.

Visitor comments