Recommendation. When replacing the clutch disc, it is advisable to replace the pressure plate as well (basket), even if there are no visible signs of wear on its working surface. The fact is that during operation, the working surface of the pressure plate wears out and the stiffness of the diaphragm spring decreases.

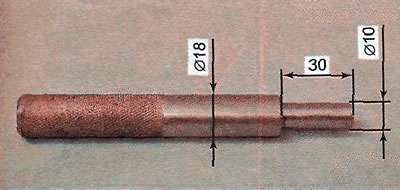

To do the job, you will need a mandrel to center the clutch disc (see «Tools, fixtures and operating materials»).

Execution sequence

1. We prepare the car for work (see «Preparing the car for maintenance and repair»).

2. Remove the gearbox (see «Gearbox - removal and installation»).

3. The presence of deep development at the ends of the petals of the central spring is the first sign that the clutch needs to be replaced.

4. If the clutch is not removed for replacement, mark the position of the basket relative to the flywheel.

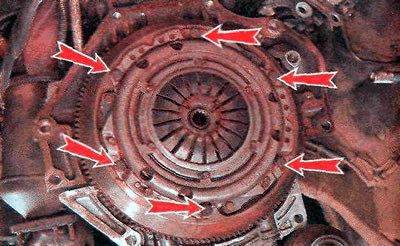

5. We screw in one of the bolts securing the gearbox to the engine and, holding the flywheel from turning with a mounting spatula or a wide slotted screwdriver, an 11 mm socket or box wrench...

... unscrew the six bolts securing the basket to the flywheel.

6. Remove the basket and driven disk.

7. Recessed rivets fastening the friction linings of the driven disk by a value less than 0.3 mm relative to the surface of the disk is the second sign of the need to replace the clutch.

During operation, the lining of the driven disk wears out. If the clutch disc is not replaced in time, the metal rivets securing the friction linings may touch the working surfaces of the pressure plate and flywheel (if, as a result of wear, the rivets are sunk less than allowed, see above), leaving furrows on them.

Having found such furrows, together with the driven disk, it is imperative to replace the basket. And if deep grooves remain on the surface of the flywheel, then the flywheel will have to be replaced (see «Rear crankshaft oil seal - replacement»). Otherwise, jerks and jerks of the car are possible even with smooth engagement of the clutch.

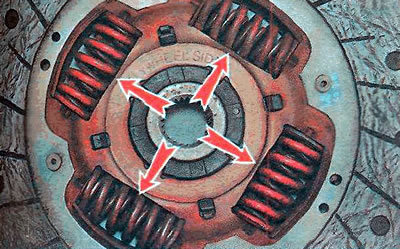

8. Loose, Cracked Vibration Damper Springs (the cause of jerks and rattling even with a smooth start of the car from a place) - the third sign of the need to replace the clutch.

9. The amount of wear on the clutch pressure plate is more than 0.2 mm - the fourth sign of the need to replace the clutch.

10. We clean the surface of the flywheel from wear products and degrease its surface.

11. Check the clutch release cylinder (see «Clutch release slave cylinder - check and replace»).

Comment. In addition to the universal mandrel for centering the clutch disc relative to the clutch basket (see «Tools, fixtures and operating materials») you can use a mandrel to center the clutch disc relative to the flywheel.

The following is a sequence of work when using this mandrel. When using a universal mandrel to center the driven plate relative to the clutch basket, install the clutch according to the instructions supplied with the mandrel.

12. We put the clutch driven disk on the mandrel in such a way that when installing the disk on the flywheel, the Getriebeseite inscription on the driven disk is on the side of the gearbox.

13. We insert the centering mandrel together with the clutch disc into the central hole of the flywheel.

14. We install the clutch basket on the flywheel and gradually tighten the bolts of its fastening to a torque of 15 Nm. If necessary, keep the flywheel from turning with a mounting spatula or a wide slotted screwdriver (see above).

15. Remove the centering mandrel.

16. Install the rest of the parts in reverse order.

Warning! When installing the gearbox, do not rest the end of the input shaft on the petals of the clutch basket spring. This can lead to clutch failure.

Visitor comments